This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

Powder Analysis

with VGSTUDIO MAX

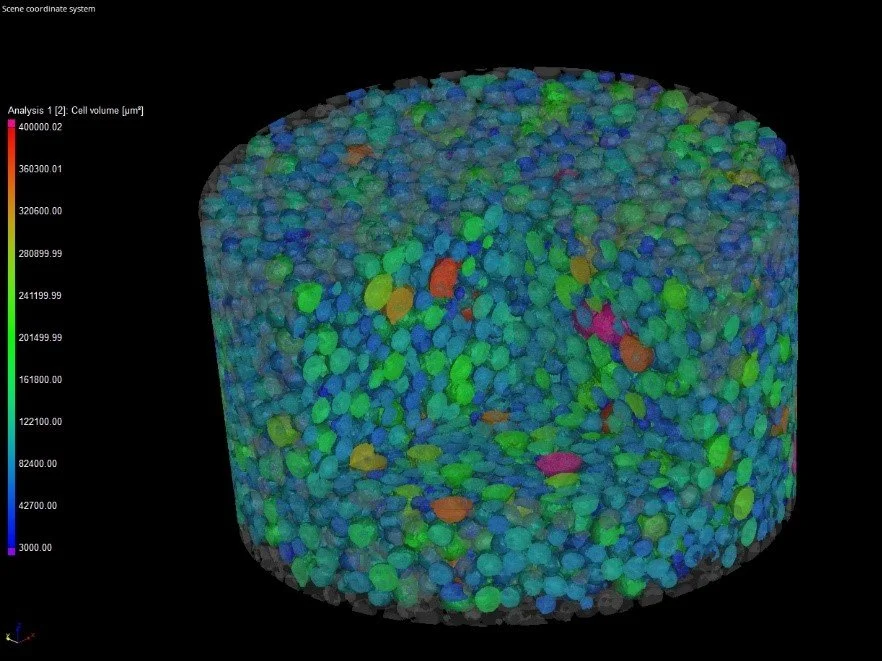

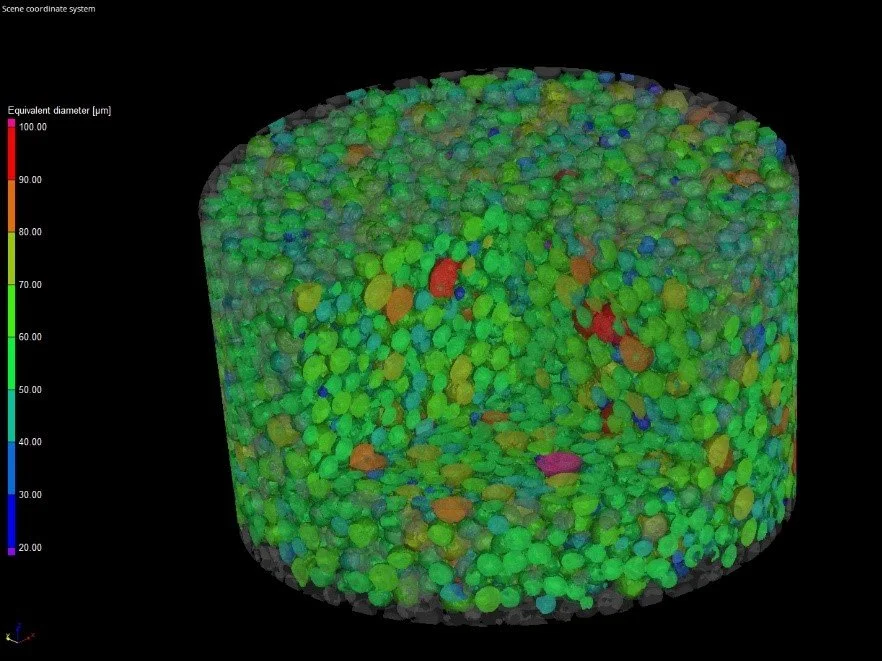

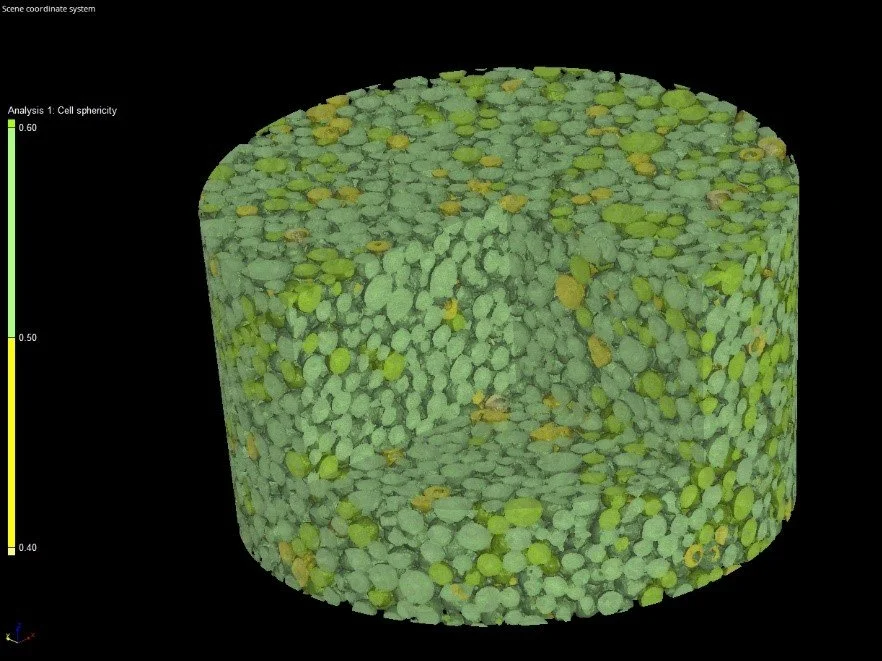

Determine grain structures in powders used in additive manufacturing, among others. The powder analysis features in VGSTUDIO MAX allow you to measure the form and size of powder particles individually, in specified groups, or in the complete powder sample and generate insightful statistics. Separate grains within powder or other granular materials to quantify them individually and determine important parameters, such as particle size, volume, surface, compactness, distributions of these parameters, and cleanliness of the powder feedstock.

Powder Analysis Features

With the powder analysis, you can:

- Measure volume, equivalent diameter, sphericity for every single powder grain and complete powder sample.

- Generate comprehensive statistics and reports.

- Create 3D visualizations of the complete CT volume and single grains.

- Create virtual 2D cross sections similar to microscopic 2D powder characterization.

- Export 2D cross sections for further analyses.

- Detect inclusions and other impurities.*

*Porosity/Inclusion Analysis Module required

Parameters for Individual Grains

You can determine the following parameters for single grains using the powder analysis:

- Position

- Volume

- Equivalent diameter (diameter of a sphere that has the same volume)

- Surface

- Mean gray value

- Sphericity

- Compactness

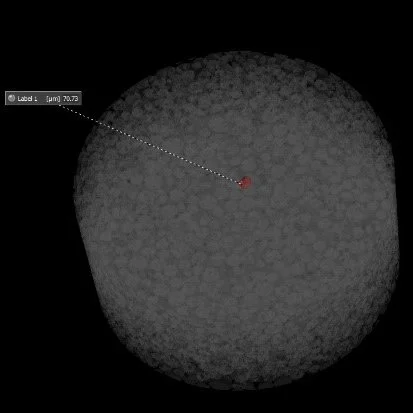

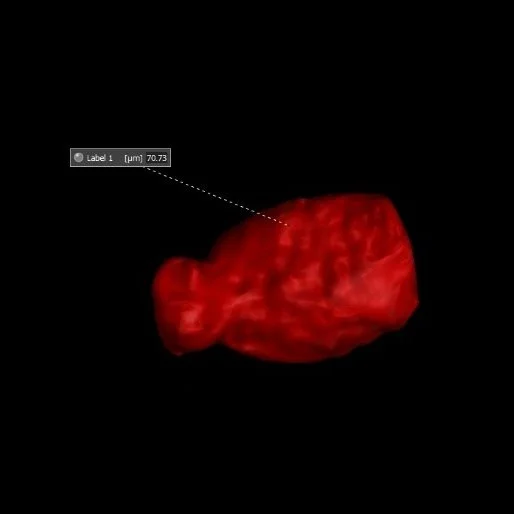

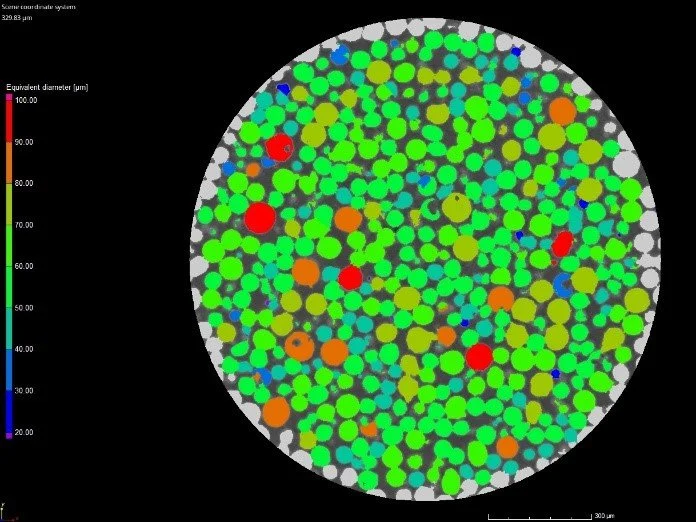

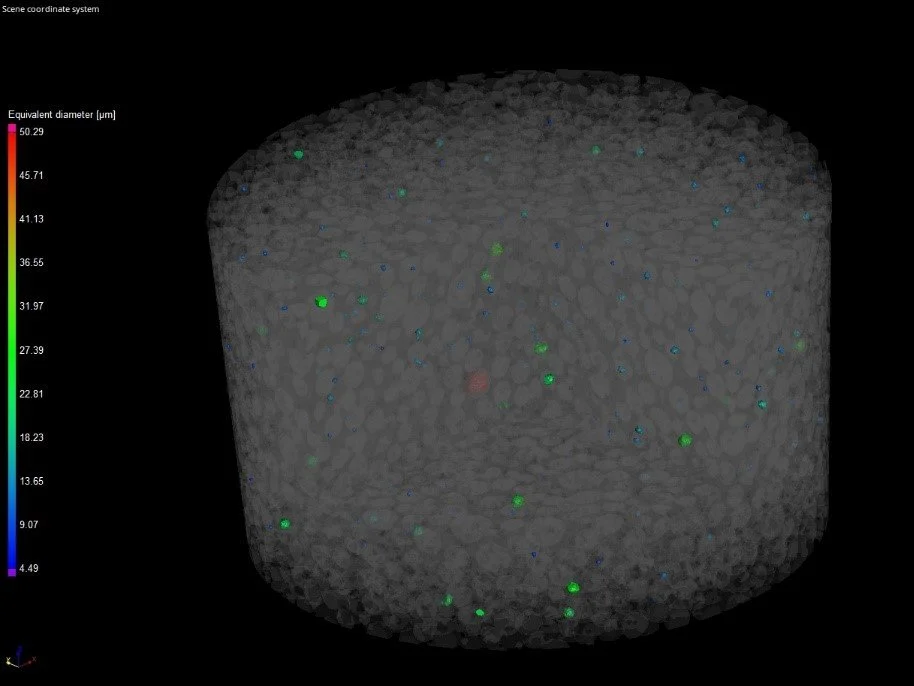

From the Complete Powder Sample to a Single Grain

With a powder analysis, you can create 3D visualizations of the complete powder sample as well as of a single grain.

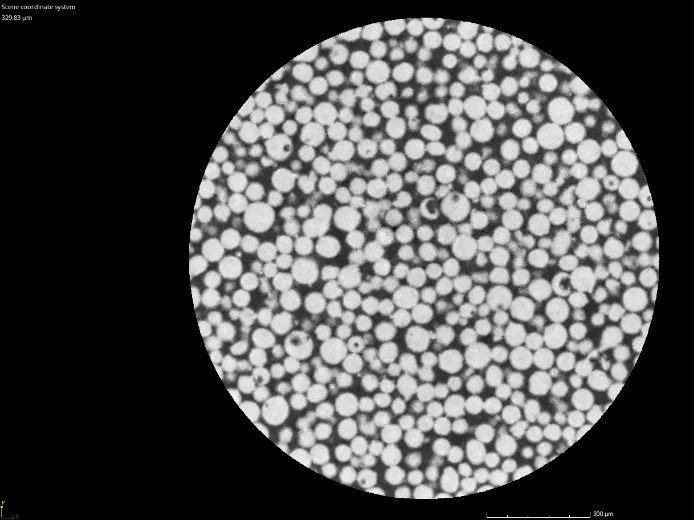

Virtual 2D Cross Sections

Create virtual 2D cross sections similar to a microscopic 2D powder characterization. For further analyses, you can export these 2D cross sections.

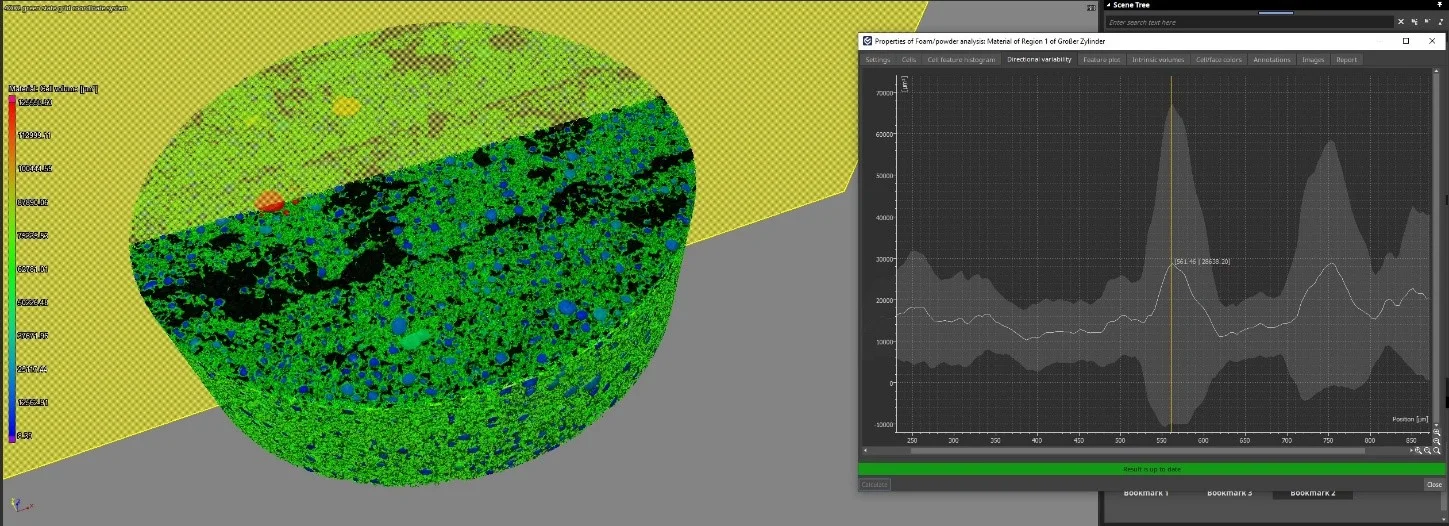

Directional Variability

Plot powder features in a certain direction to investigate, among others, parts manufactured by binder jetting. In this case, the process-induced distribution of powder in the green part.

Detection of Inclusion and Other Impurities

With the additional porosity/inclusion analysis module, you can also detect porosity within powder grains and impurities in the powder sample, such as inclusions of foreign material.

Statistics

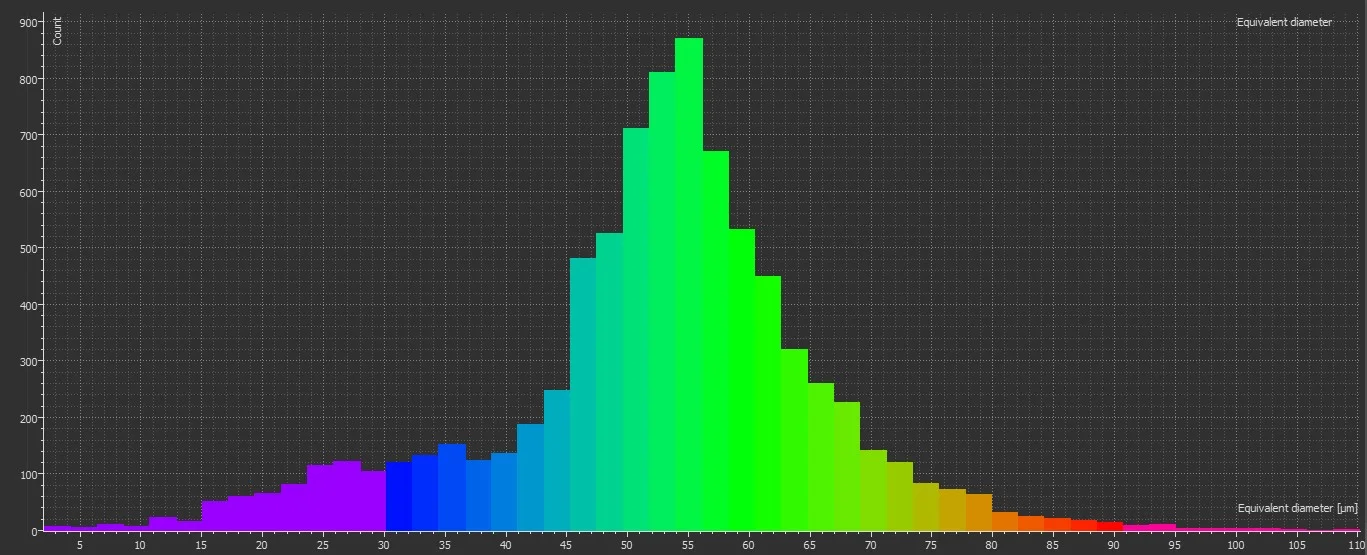

Histograms

The distribution of the values of a corresponding grain parameter can be displayed using histograms. In the following example, which is a CT scan of a Ti6Al4V powder sample, the distribution of the equivalent diameters of the powder grains can be seen.

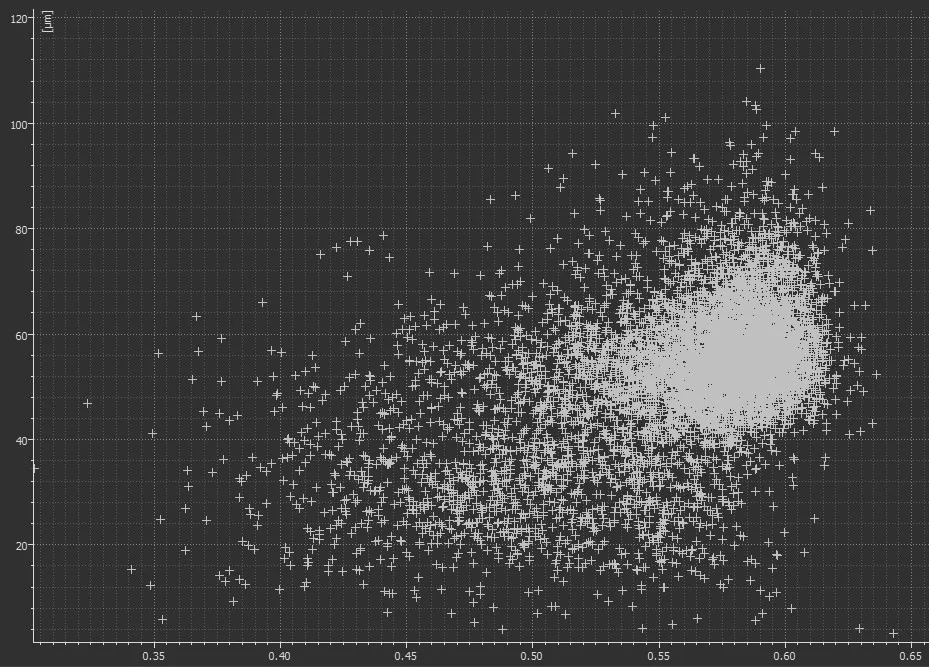

Feature Plot

Via the X-Y-Plot, you can easily visualize dependencies between grain parameters. For example, the dependency between sphericity and equivalent diameter can be helpful in understanding progressive powder aging and evolving powder satellite formation.

Benefits

- Comprehensive and accurate 3D characterization of morphology and size for every powder grain without having to physically isolate the grains

- Complete statistics, histograms, and feature plots on all measured grain parameters

- Analysis can be automated to ensure consistent results and reporting of analyses taken over time