This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

Digital Volume Correlation

with VGSTUDIO MAX

Quantify displacements between an initial and a deformed volume in a simple, intuitive way. With the digital volume correlation features in VGSTUDIO MAX, you can calculate the movement of each voxel from one volume to another for the analysis of in-situ tests or part deformation based on real world component loads. The software measures local displacement and strain tensors, visualizes deformations and movements via displacement arrows or lines, and maps results onto finite element (FE) meshes to validate your simulations.

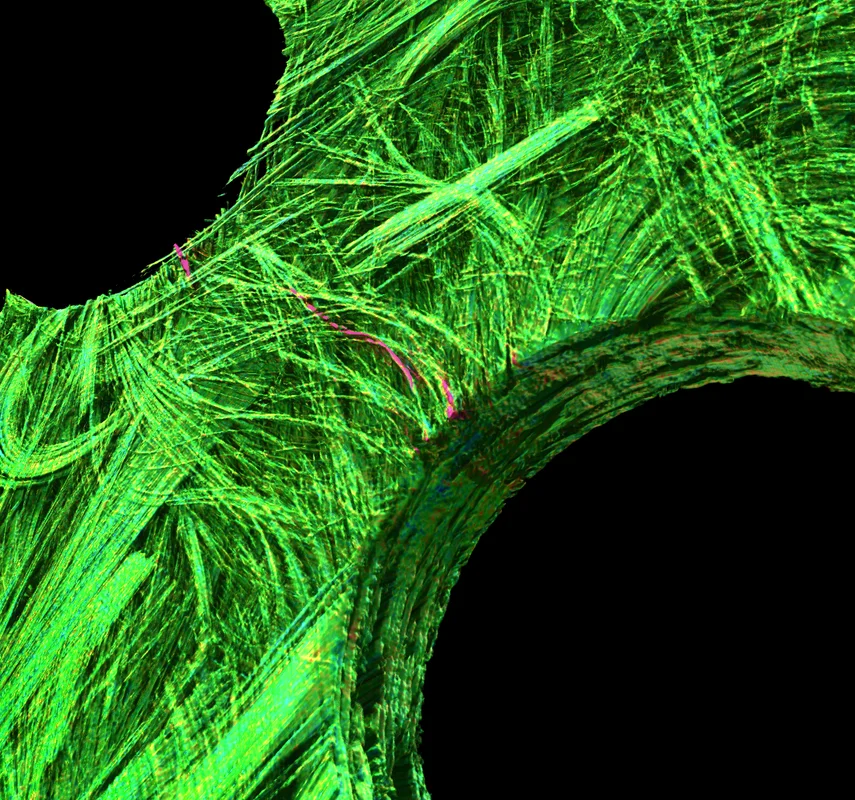

Identify cracks in your parts. With semi-automatic crack segmentation, you can quantify cracks in your scans. By using multiple scans, you can compare these data sets and detect defects that can’t be seen with the naked eye. Defects can be characterized, for example, by their surface.

Digital Volume Correlation Features

The digital volume correlation analysis:

- Correlates volumes at different states to calculate displacements and strains.

- Allows you to investigate local strains to fit or validate material models in material science.

- Is a powerful tool for damage detection in composite materials, making it possible to investigate small cracks by comparing gray values in two different states.

- Matches material (e.g., bones) between different states in life science to study growth or other structural changes.

- Offers two different correlation approaches to match volumes with the same image modality (e.g., two CT scans) or with different image modality (e.g., CT scan and MRI).

Investigating Deformations

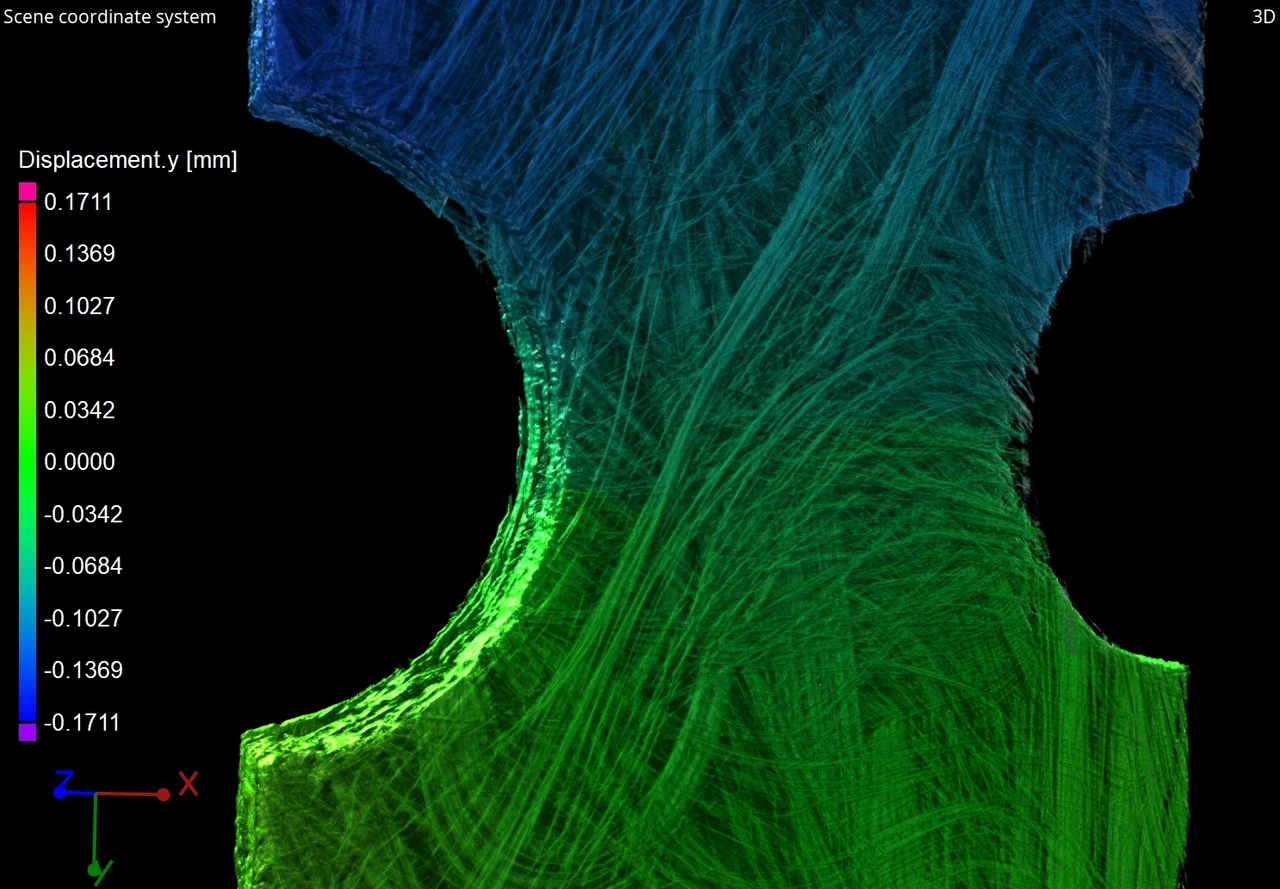

Displacements and Strains

Calculate and visualize displacements as well as strains.

With the digital volume correlation analysis, you can:

- Calculate local displacements from a non-linear transformation.

- Visualize and measure local displacements in each coordinate direction, either component-wise or based on the displacement magnitude.

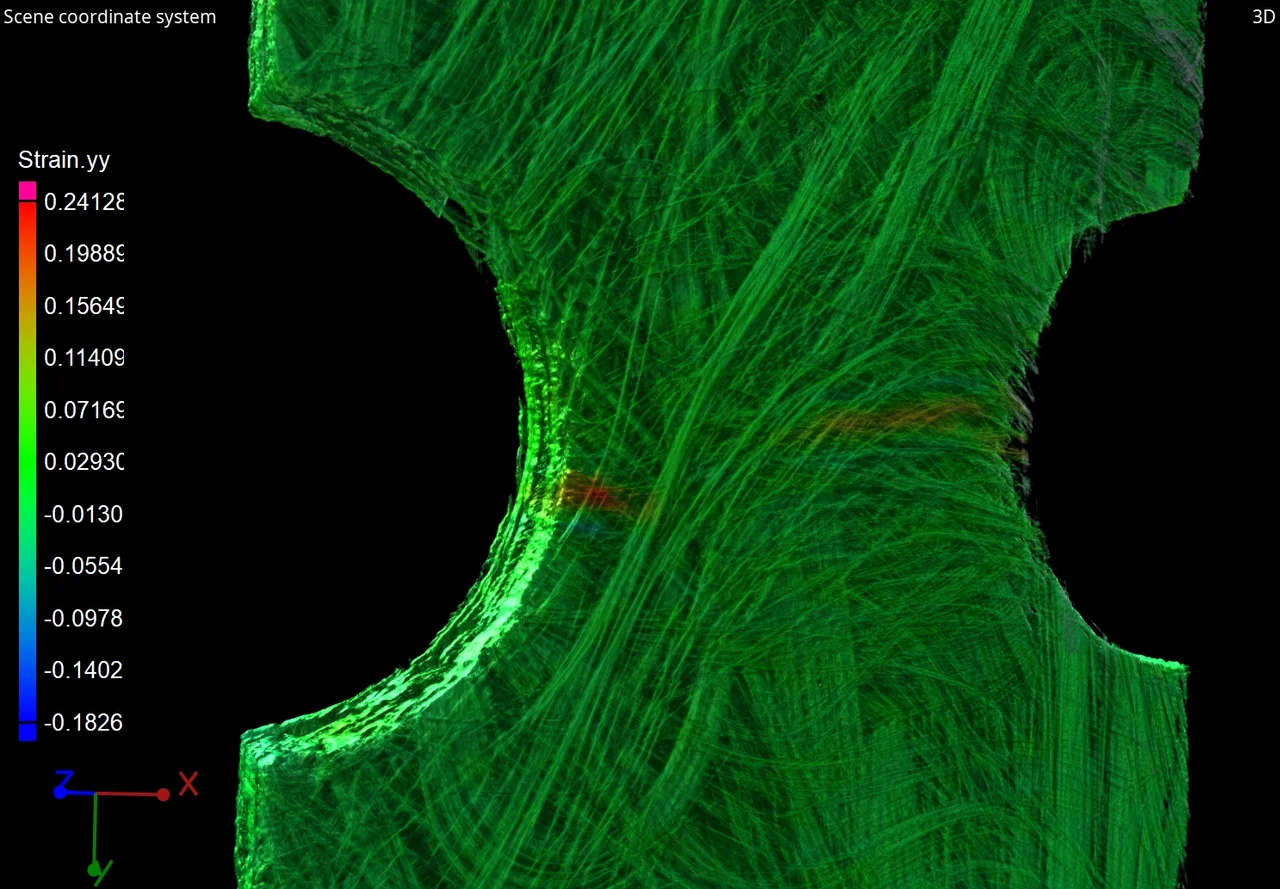

- Visualize three-dimensional local strain tensors component-wise (xx, yy, zz, xy, xz,yz).

- Calculate von Mises strain and maximal, middle, and minimal principal strains.

Visualize and measure local displacements

Visualize dimensional local strain tensor components

Finite Element (FE) Meshes

To compare strains with simulation results or to fit material models, you can map local deformations or strains directly onto FE meshes. This makes VGSTUDIO MAX a powerful tool for material modeling.

With VGSTUDIO MAX, you can:

- Directly compare results with simulations.

- Validate and improve material models.

- Import Patran, NASTRAN, or Abaqus, meshes to map strains on the same meshes used for simulation.

- Quickly generate rectangular meshes to average strains over a certain region and use the results for analytical models.

- Map results onto meshes generated by the VGSTUDIO MAX Volume Meshing Module.

- Map microstructure information like fiber orientation and fiber volume fraction of the very same sample onto the same mesh in a seamless workflow.

Workflow for Validation (or Fitting) of Material Models

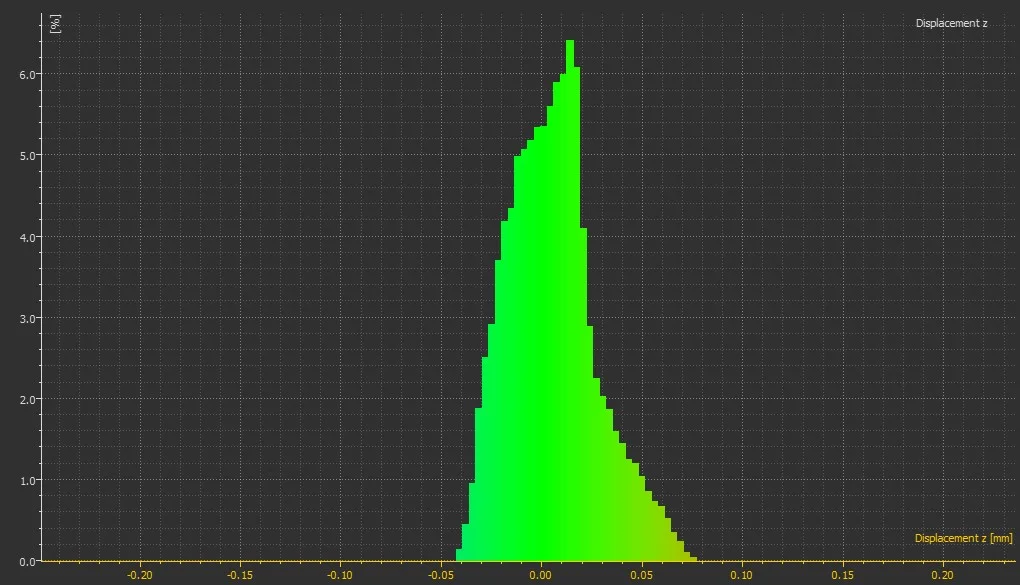

Histograms

All local features can be used to create local histograms for selected regions of interest or global histograms for the entire volume. Histograms allow you to investigate the distribution of displacement and strain globally over the analysis region.

Detecting Defects

With digital volume correlation analysis, you can:

- Detect defects invisible to the naked eye, such as cracks within the microstructure.

- Separate and quantify these cracks by surface, volume, and shape* and use the results for damage modeling.

- Gain full information of the microstructure, like fiber orientation and volume fraction, from the undamaged sample using further material analysis features available in VGSTUDIO MAX.

*Porosity/Inclusion Analysis Module required

Benefits

Versatile

- Allows strain measurement for in-situ testing to validate material models for FE simulations.

- Allows you to detect damage, like small cracks between fibers.

- Can be used in maintenance applications to find inner damage by comparing scans of the same component as manufactured vs. after use for a certain period of time

Accurate

- Measure 3D displacement with subvoxel accuracy.

- Provides accurate results even on low-contrast data sets.

Easy-to-use

- Graphical illustrations and recommendations make it quick and easy to find the best settings for your particular task.

- Easily map digital volume correlation results on your FE meshes and export them in a .csv file.

- Generate stunning visualizations using color overlays or displacement lines.