This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

Version 3.5.1: Introducing Ambient Occlusion, New P 203 Analysis Functions, and More Customizable Report Layouts

Volume Graphics introduces the next version of its product family for the analysis and visualization of industrial computed tomography (CT) data: Version 3.5.1 of VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, and VGinLINE. In version 3.5.1, users can look forward to ambient occlusion for more realistic shading in 3D renderings, the option to select and remove fit points using ROIs, better uniform control point distribution in mesh compensation, new P 203 analysis functions, multi-user support for VGinLINE APPROVER, and more customizable report layouts, among other new and exciting features.

Ambient Occlusion

Ambient occlusion gives 3D renderings in Volume Graphics applications more realistic shading and a feeling of depth. Without noticeable impact on performance, the shading and rendering technique calculates how exposed to ambient lighting each point in a scene is. This provides realistic depth perception. It also improves the orientation in complex models and helps when visually inspecting and navigating in the 3D view.

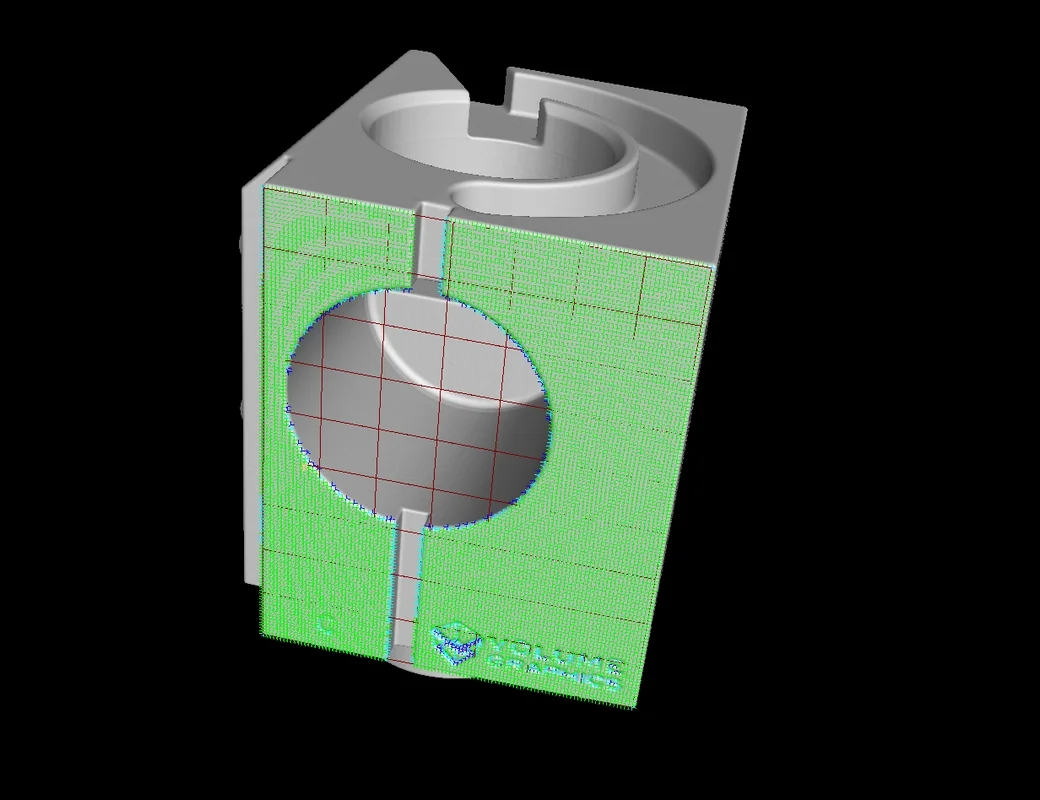

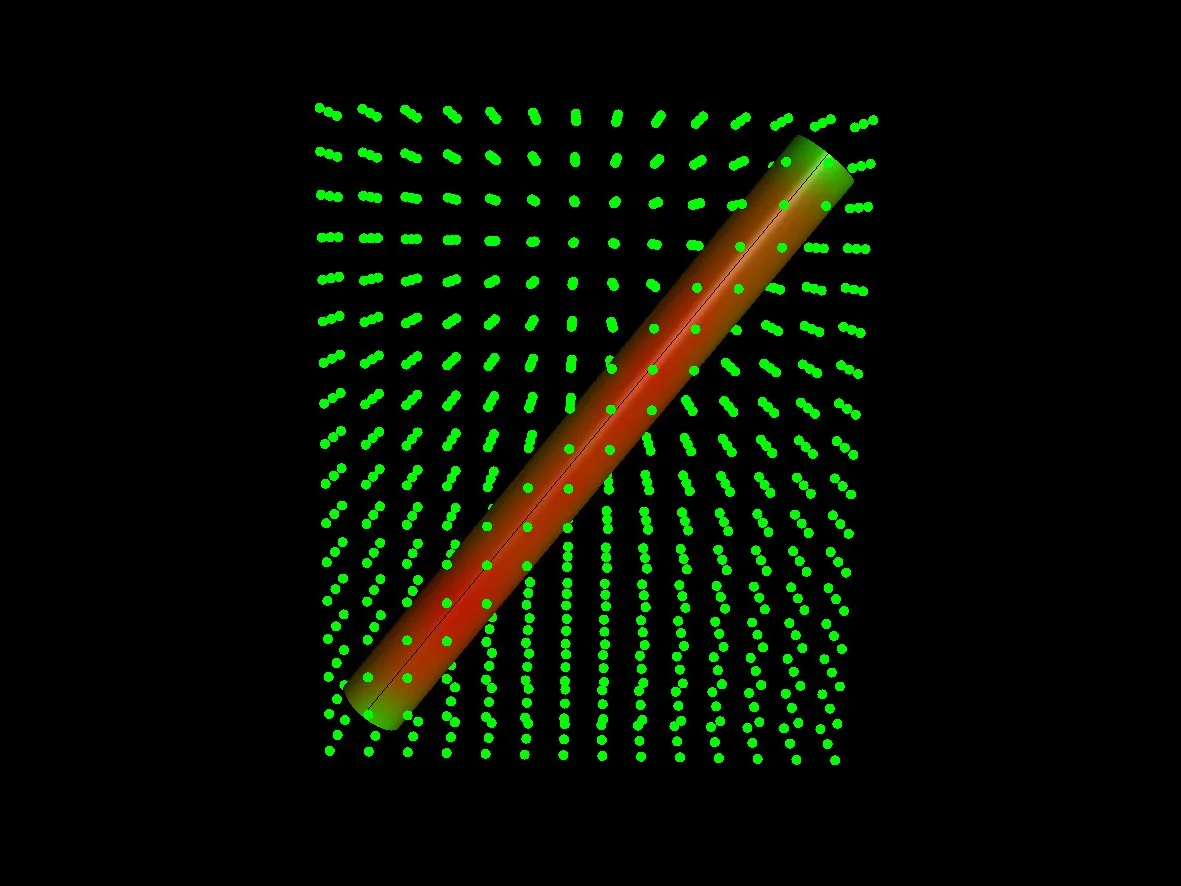

Select and Remove Fit Points Using ROIs

Users can now eliminate fit points in a specific area or only select fit points in a specific area. This allows users to avoid using points that do not belong to the feature or represent artifacts. To define the selection, users can use the complete set of ROI functions.

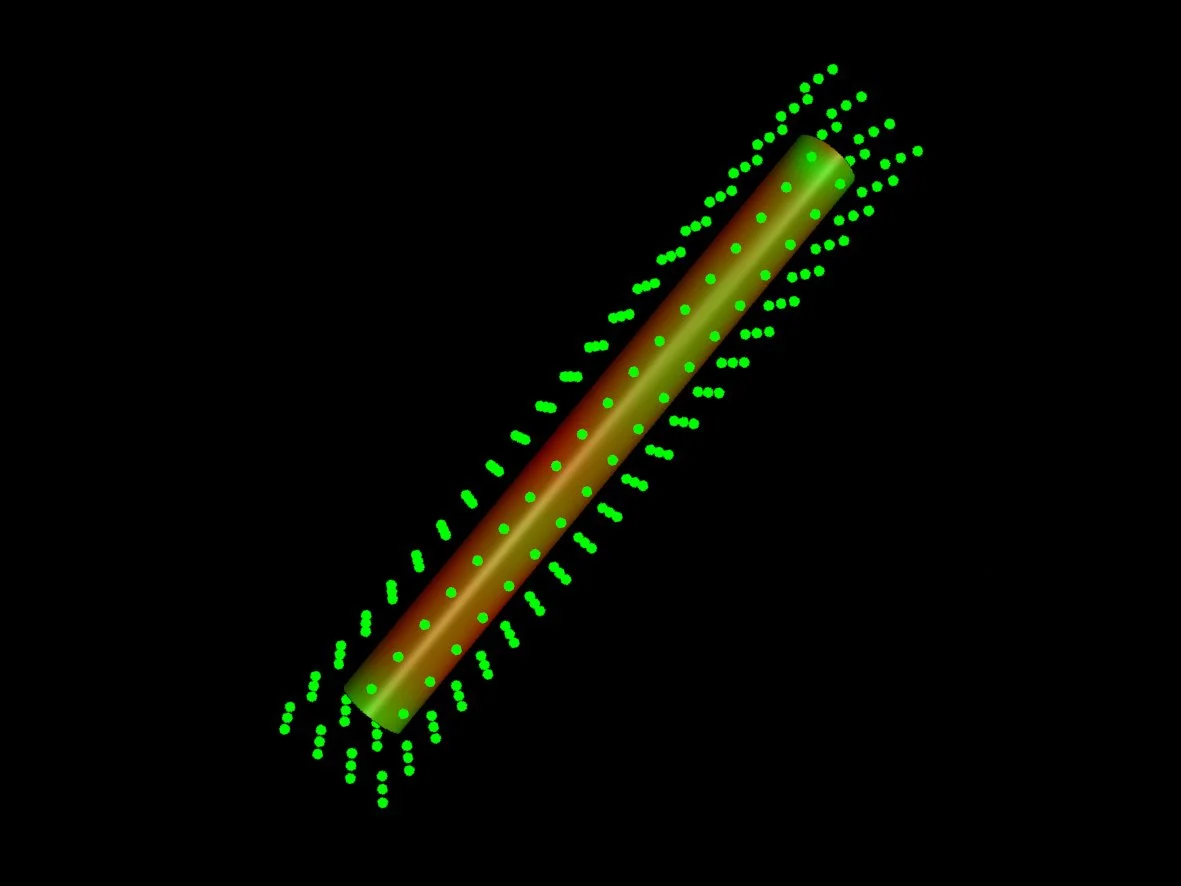

Improved Tool Correction and Mesh Compensation

- Better uniform control point distribution in mesh compensation: When compensating a mesh using the uniform control point method, control points are now better aligned to the part, which reduces the number of points needed while producing better results.

- Eliminating the need for nominal/actual comparison between nominal and mold: Tool correction can now be performed without performing a nominal/actual comparison between nominal and mold in advance.

New P 203 Analysis Functions

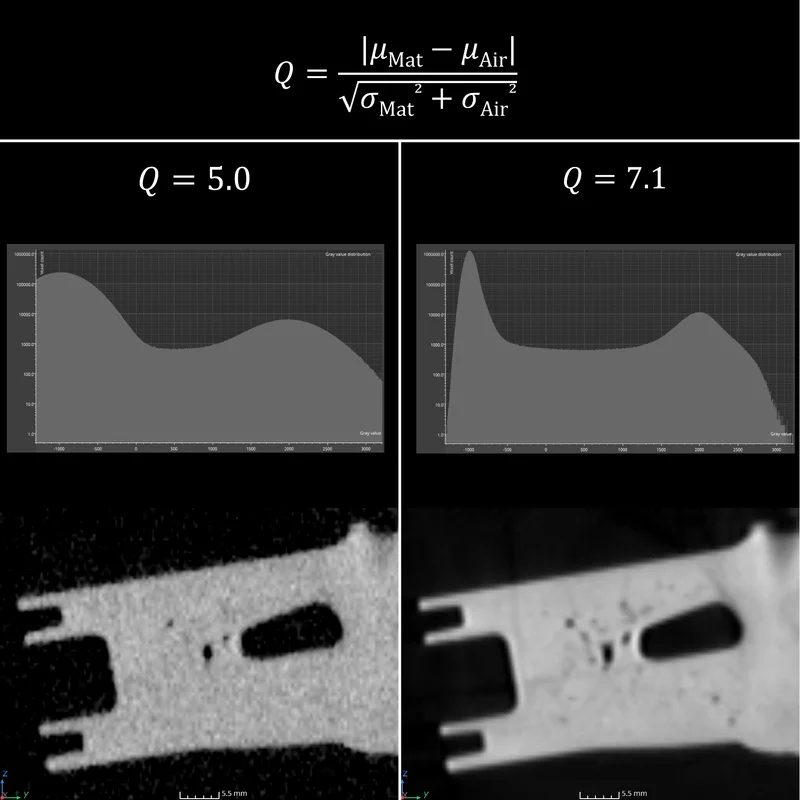

- Support of the quality factor Q acc. to BDG P 203: The Q factor is a simple approach for verifying the quality of the gray value volume and documenting the quality of CT scan data.

- Users can now automatically display the BDG P 203 porosity key and the analysis results for each analyzed freeform partial volume in 3D and 2D.

- In the porosity analysis acc. to BDG P 203, users will now receive the number of NOK ("not okay") pores for selected porosity parameters that are out of tolerance.

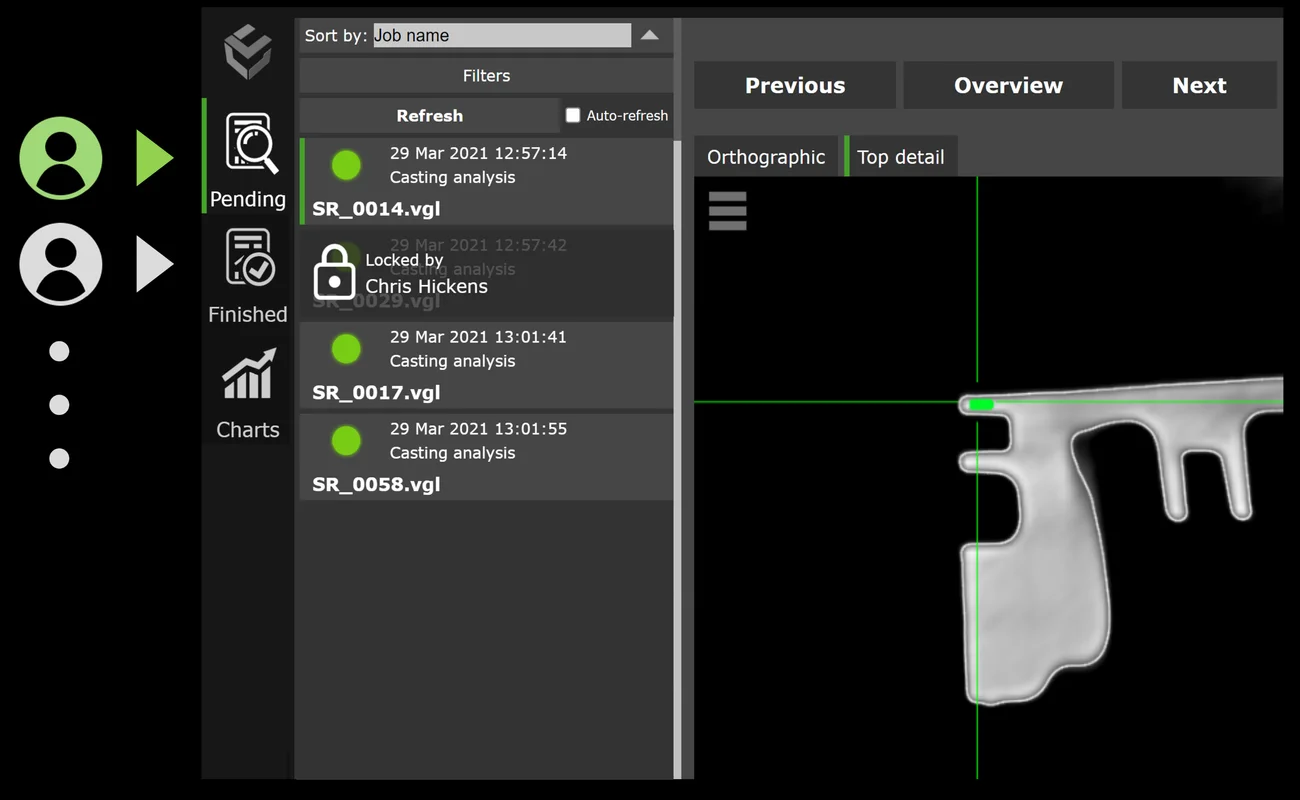

Multi-User Support for VGinLINE APPROVER

Users can now access the VGinLINE APPROVER web application while other users are also working with it. Multi-user support improves general efficiency by removing the need for coordination between users and increasing throughput through parallel work in the system.

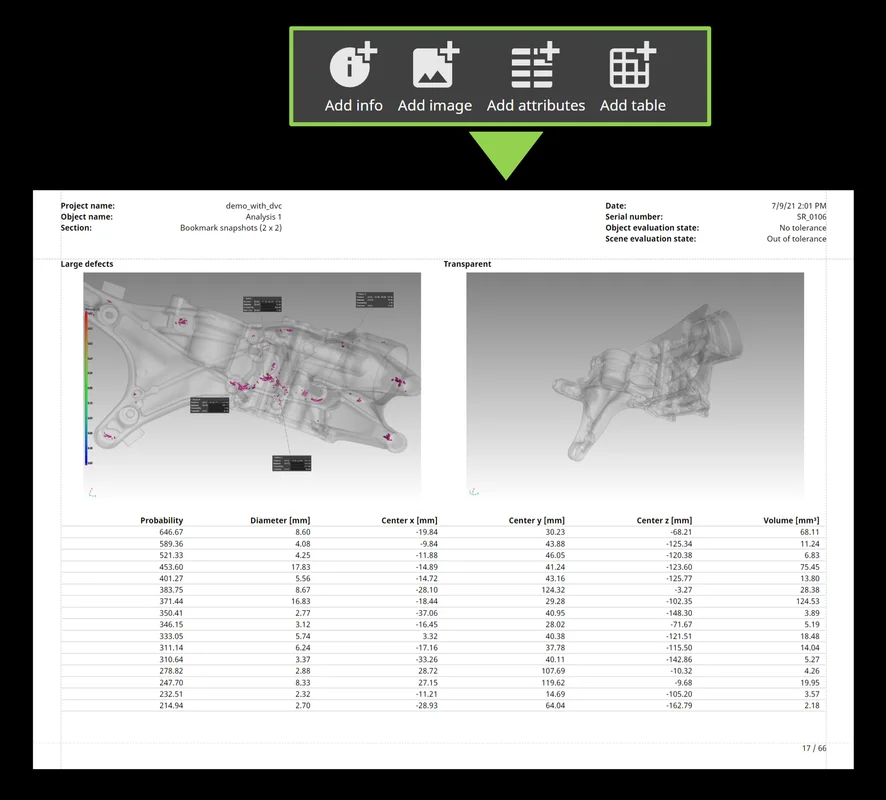

More Customizable Report Layouts

Create entirely new report page layouts by combining arbitrary information from reported objects, for example, to create overview sections or sections that contain multiple result images of a part. Users can choose from images, attributes, tables, and info fields and arrange them flexibly to customize the way results, settings, images, and other information are presented on report pages.

*Depending on the platform, there may be differences in the range of functions for different operating systems. See our continuously updated Product Information page for more details.

Learn More

Learn in detail about what's new in version 3.5.1 on our dedicated overview pages for: VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, and VGinLINE.

Availability of the New Version

VGSTUDIO MAX 3.5.1, VGSTUDIO 3.5.1, VGMETROLOGY 3.5.1, and VGinLINE 3.5.1 are available now. Volume Graphics is happy to provide quotes upon request.

Volume Graphics offers free evaluation versions of VGSTUDIO MAX 3.5.1, VGSTUDIO 3.5.1, and VGMETROLOGY 3.5.1 for temporary use.

myVGL 3.5.1 is available free of charge and can be requested on the Volume Graphics website.

About Volume Graphics and Hexagon

Volume Graphics GmbH has been developing software for non-destructive testing based on industrial computed tomography (CT) for over 20 years. Customers around the world, e.g., from the automotive, aerospace, and electronics industries, use Volume Graphics software for quality assurance in product development and production. In addition to its headquarters in Heidelberg, the company has branches in the USA, Japan, Singapore, and China. Learn more at www.volumegraphics.com and follow us @volume_graphics.

Since 2020, Volume Graphics has been part of Hexagon. Hexagon is a global leader in sensor, software and autonomous solutions. We are putting data to work to boost efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications. Our technologies are shaping urban and production ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 21,000 employees in 50 countries and net sales of approximately 3.9bn EUR. Learn more at hexagon.com and follow us @HexagonAB.