This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

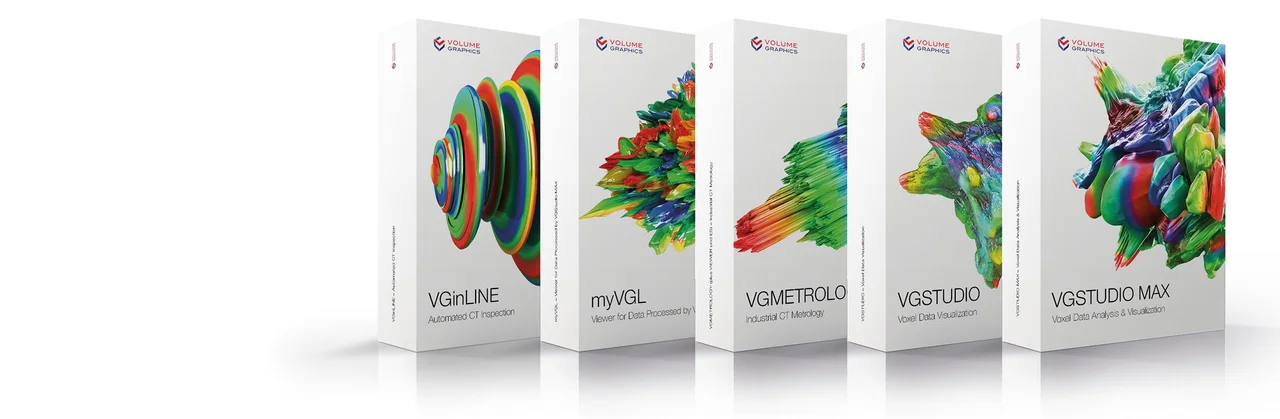

With the Volume Graphics product family, all kinds of analyses and visualizations can be carried out directly on data from industrial computed tomography (CT).

Version 3.4.5: Introducing P 203 Analysis

Version 3.4.5 of VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, VGinLINE, and myVGL is now available for download. In version 3.4.5, you will benefit from the following new capabilities*:

- Support of BDG Reference Sheet P 203: The new P 203 analysis of our Extended Porosity/Inclusion Analysis Module allows you to inspect cast parts for porosity according to the Reference Sheet P 203 of the Federation of German Foundry Industry (BDG). It also allows you to perform a 3D evaluation with regard to the most critical defect parameters in functional areas of the part. Together, VGSTUDIO MAX and Q-DAS qs-STAT now cover the complete loop—from specifying porosity tolerancing criteria according to P 203 by the product designer to statistical process control by the quality engineer:

- Generate porosity keys via an intuitive interface, define a reference volume according to the inspection plan using the ROI functions of VGSTUDIO MAX, and get a quick overview of all global tolerancing criteria and results for the P 203 analysis.

- Evaluate defects and independently tolerance different ROIs in one P 203 analysis, flexibly combine the tolerancing and filtering of defects based on their characteristics, and evaluate only freeform reference volumes (ROIs) within the object's boundaries (surface).

- Document P 203 analysis results by using "Reporting via Excel"—or the new integrated reporting function.

- Export P 203 analysis results to Q-DAS to qualify and statistically analyze your casting processes.

- Q-DAS export for all global porosity/inclusion analysis results: export toleranced, global porosity/inclusion analysis results and related tolerances in Q-DAS ASCII transfer format for process qualification or statistical analysis in statistics software, such as qs-STAT from Q-DAS.

- ROI-specific histograms for volume mesh element quality: inspect tetrahedral mesh element quality and element size specifically within an ROI by only creating element quality histograms for elements within the defined ROI.

- NASTRAN export for volume meshes: use tetrahedral volume meshes created in VGSTUDIO MAX for NASTRAN simulation models based on CT data without any conversion from FE preprocessor software.

- TXM volume import: directly import high-resolution volume data from ZEISS Xradia CT systems, including correct settings for orientation and dimensions.

- Visit the "What's New" page for VGSTUDIO MAX 3.4 to learn more about these and other new features in version 3.4.5, such as easy mesh comparison through retained ROI selection, image generation settings for the new reporting function, a zoom function in the report editor, and window options when saving images.

- Discover the new features of the other products in version 3.4.x on our "What's New" pages for VGSTUDIO 3.4, VGMETROLOGY 3.4, and VGinLINE 3.4.

*Depending on the platform, there are differences in the range of functions for different operating systems. See our continuously updated Product Information page for details.

Availability of the New Version

VGSTUDIO MAX 3.4.5, VGSTUDIO 3.4.5, VGMETROLOGY 3.4.5, and VGinLINE 3.4.5 are available now. Volume Graphics is happy to provide quotes upon request.

Volume Graphics offers free evaluation versions of VGSTUDIO MAX 3.4.5, VGSTUDIO 3.4.5, and VGMETROLOGY 3.4.5 for temporary use.

myVGL 3.4.5 is available free of charge and can be requested on the Volume Graphics website.

About Volume Graphics and Hexagon

Volume Graphics GmbH has been developing software for non-destructive testing based on industrial computed tomography (CT) for over 20 years. Customers around the world, e.g., from the automotive, aerospace, and electronics industries, use Volume Graphics software for quality assurance in product development and production. In addition to its headquarters in Heidelberg, the company has branches in the USA, Japan, Singapore, and China. Learn more at www.volumegraphics.com and follow us @volume_graphics.

Since 2020, Volume Graphics has been part of Hexagon. Hexagon is a global leader in sensor, software and autonomous solutions. We are putting data to work to boost efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications. Our technologies are shaping urban and production ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 21,000 employees in 50 countries and net sales of approximately 3.9bn EUR. Learn more at hexagon.com and follow us @HexagonAB.