No one likes pores—even on CT scans. But as long as they don't compromise the stability of the part, we can live with them. This applies especially in castings, injection moldings, welding seams, and composite materials.

But what about inclusions? They have a better reputation, because they are usually intentional. For example, in composite materials like concrete, they reinforce the structure.

Concrete is a composite material with inclusions.

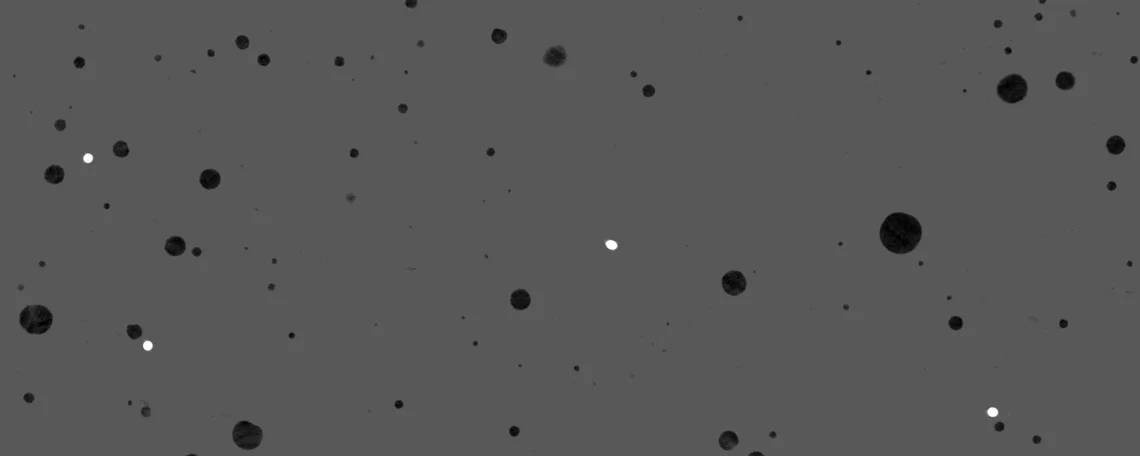

But what if inclusions are not intentional? Like a grain of sand from a mold, or even worse—a crystalline form of aluminum oxide that comes from the inner brick walls of a furnace. Either way, although it is not critical for casting, it could cause serious damage to your milling tool if it touches the particle during machining.

Sand grains (bright spots) in an aluminum casting

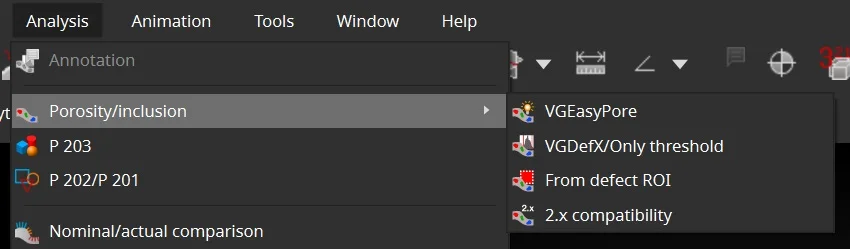

Porosity/Inclusion Analysis

VGSTUDIO MAX offers a few calculation approaches for voids and inclusions, but by default, none of them shows inclusions and porosity simultaneously. We could run two analyses—one for pores, one for inclusions—but then we would end up with two separate statistics, which makes it difficult to examine all defects at a glance.

Porosity/inclusion analyses in VGSTUDIO MAX

But is it possible to have your cake and eat it too? The answer is yes!

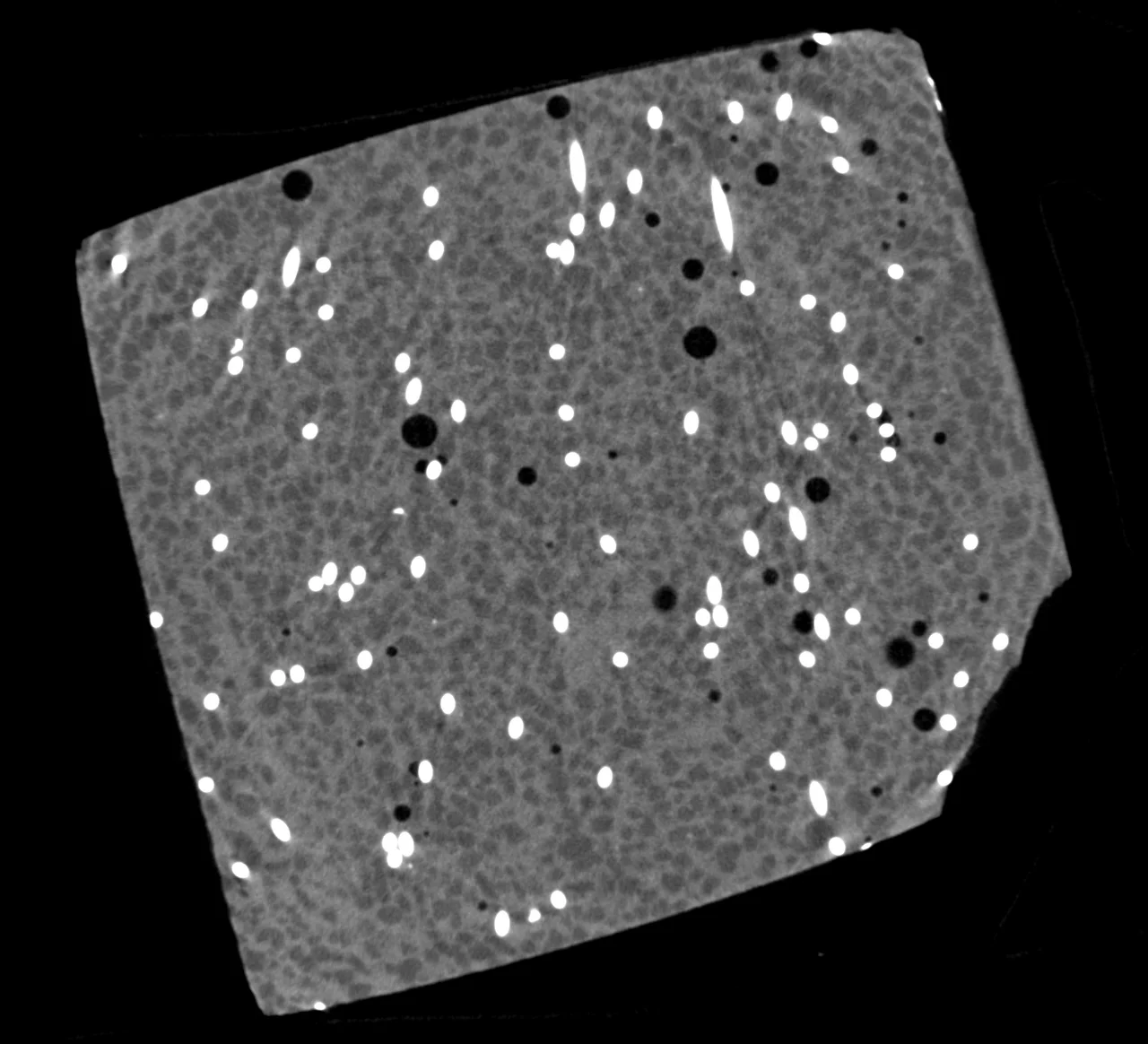

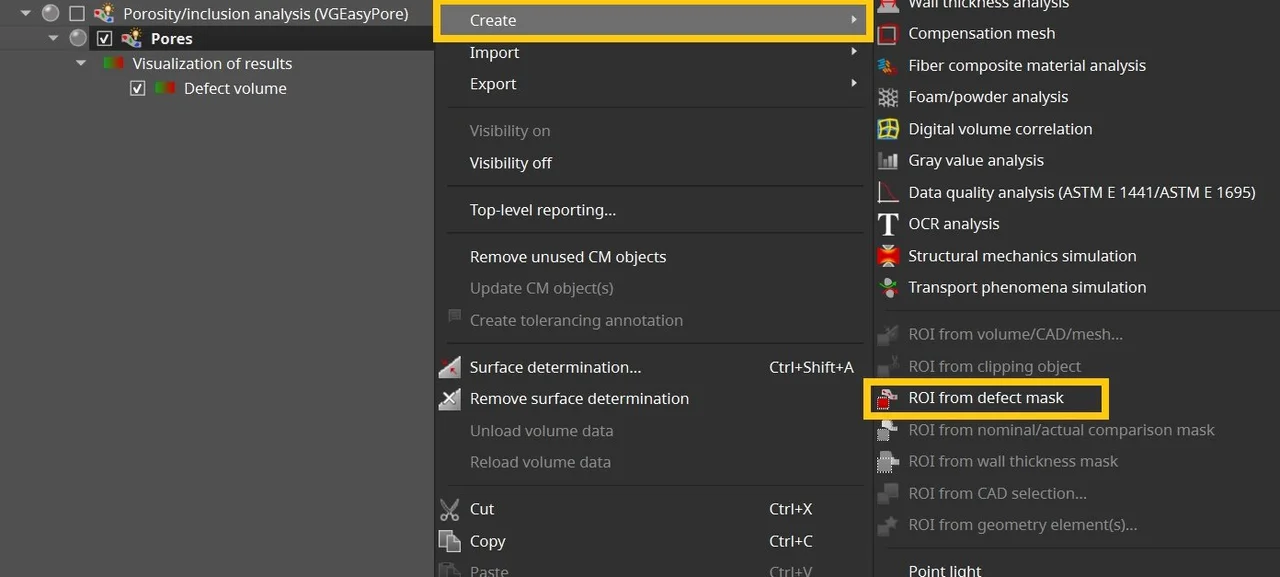

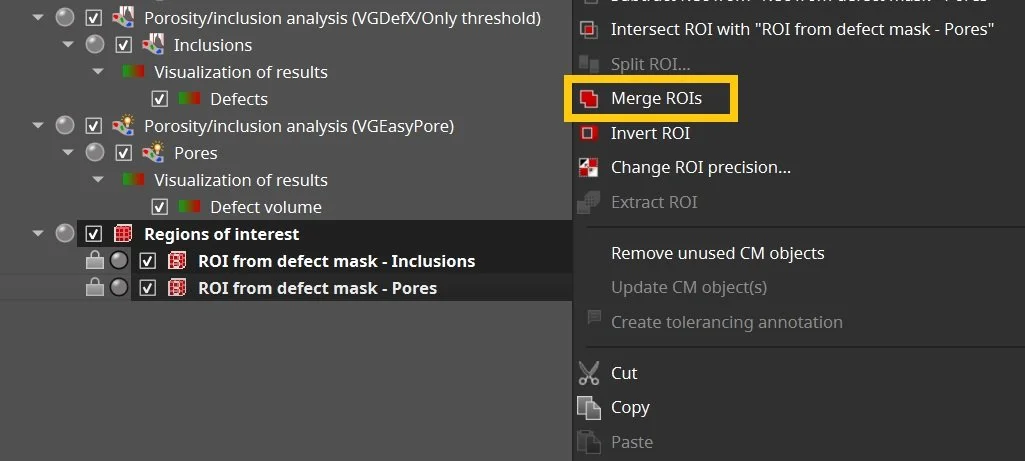

First, we can start with two separate analyses: one for voids, one for inclusions. Then we can create an ROI from each defect mask. It takes the shape of the discovered defects and creates a region out of them. This way, we end up with two ROIs: one for the voids, another for the inclusions. Now you can merge them!

This is how you create ROIs from the defect mask...

...and this is how you merge them.

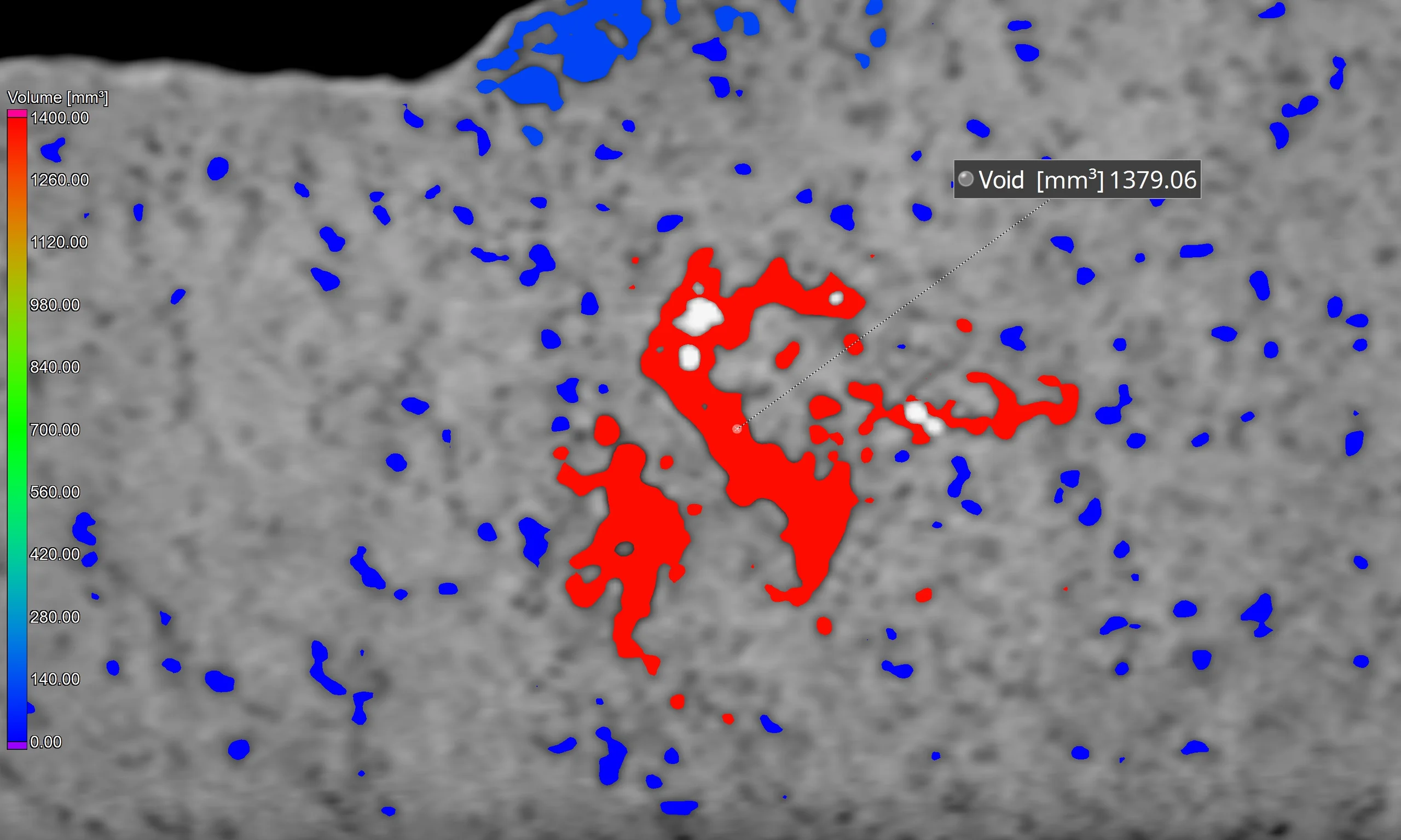

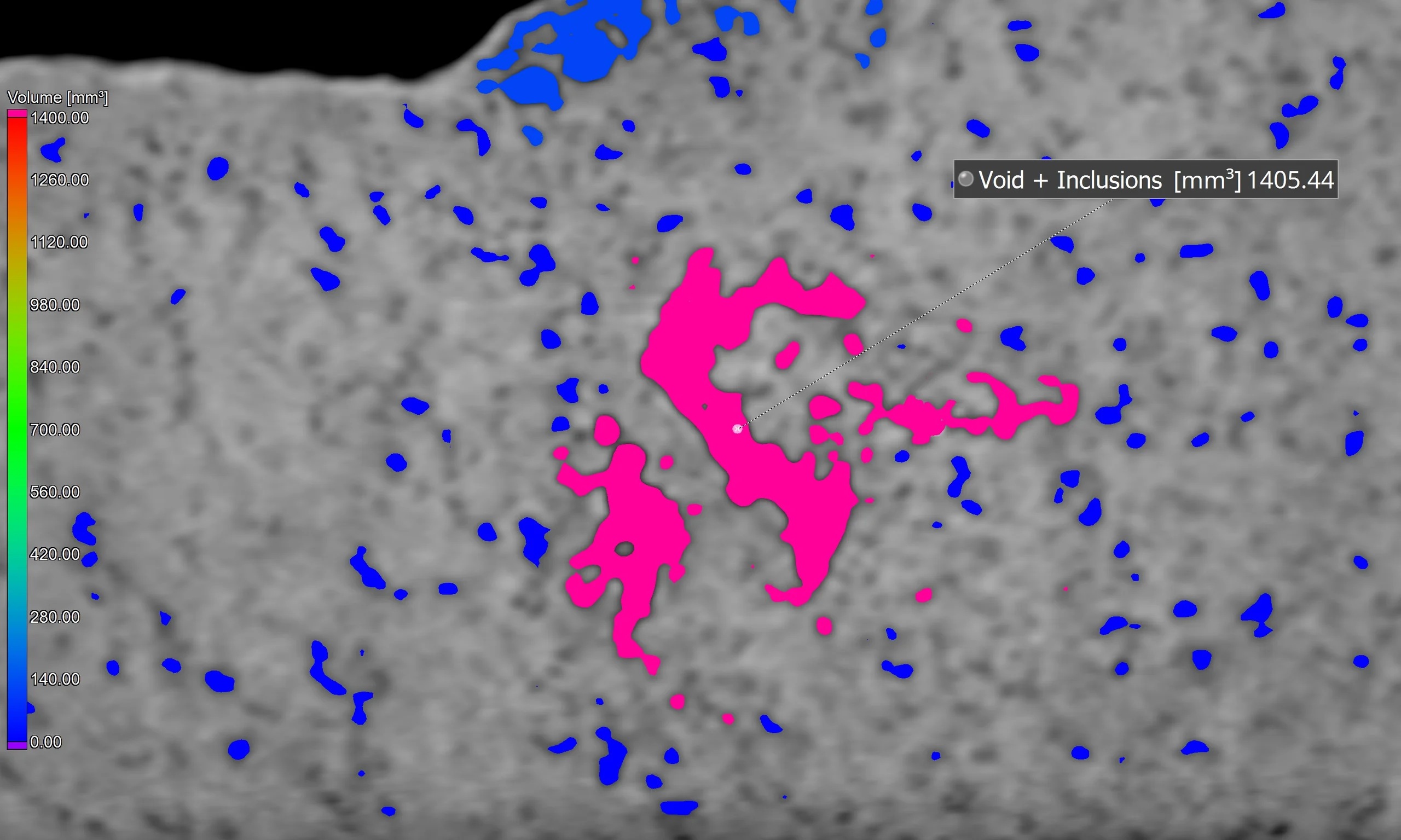

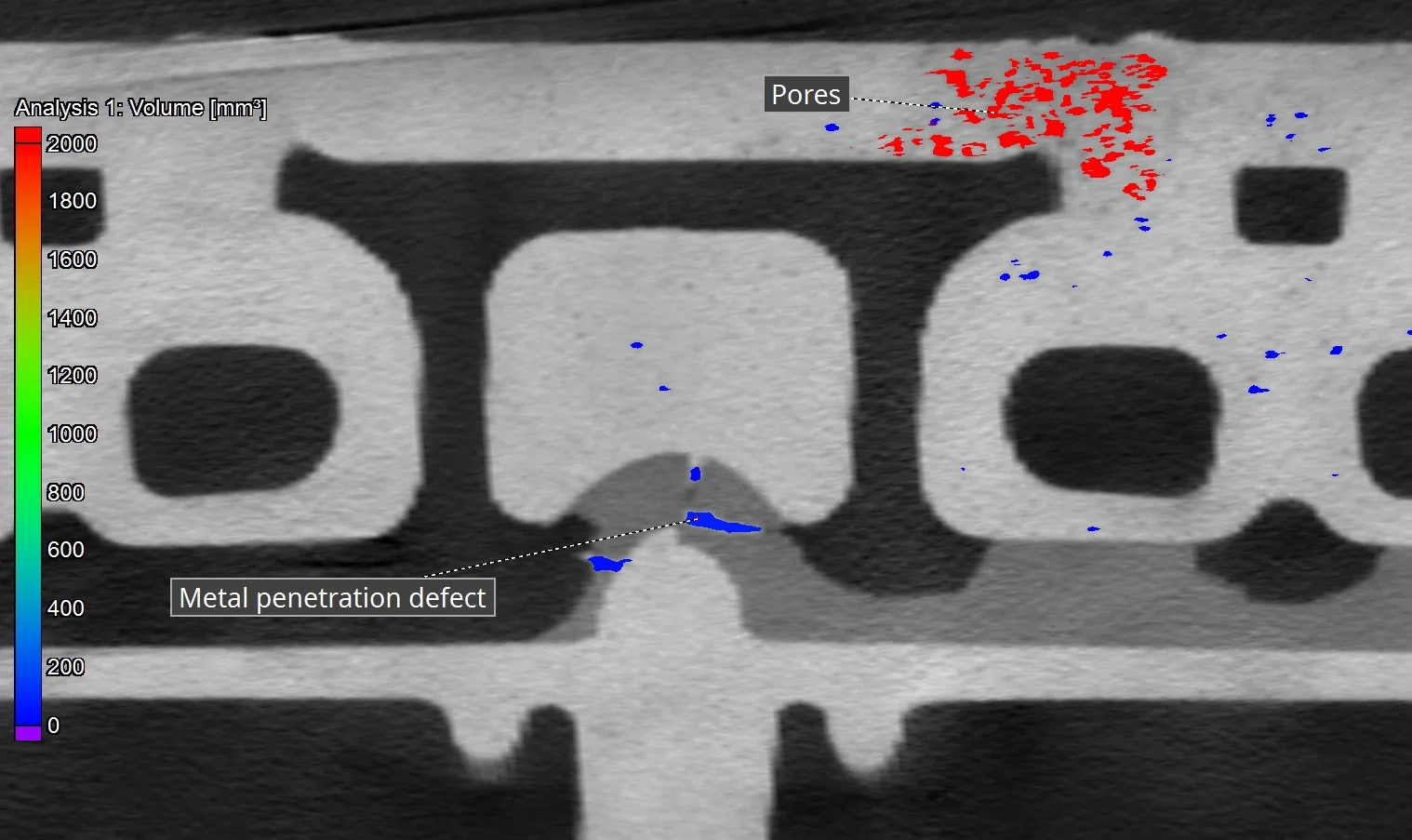

Select the newly merged ROI and run a "From defect ROI" porosity/inclusion analysis. That’s it! Now every piece of the selected ROI is counted as a defect and is included in the statistics no matter what—void or inclusion.

Oh, by the way, you can record it as a macro to make your daily workflow even more efficient.

Compare: "voids only" vs "voids and inclusions combined in one analysis"

Did You Know? From Defect ROI

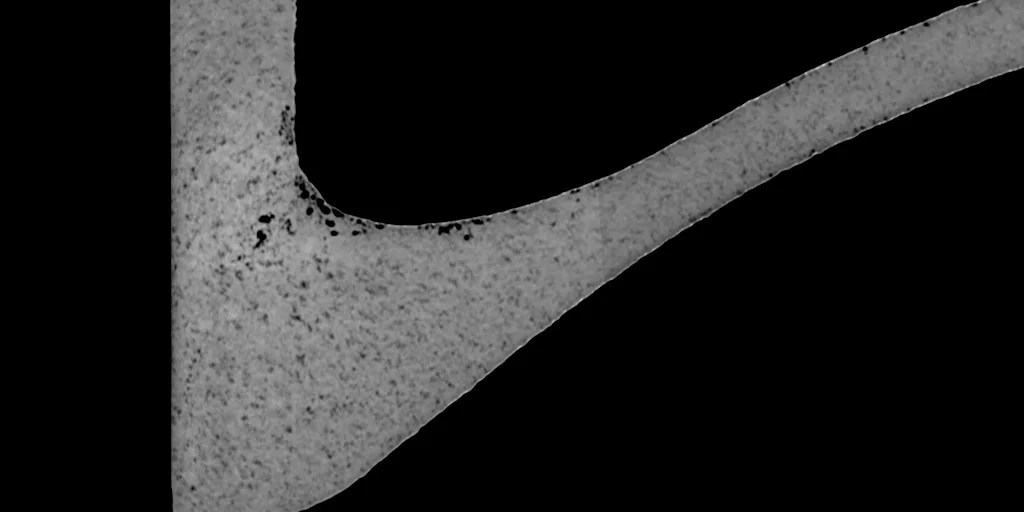

The porosity/inclusion analysis "From Defect ROI" is very straightforward: it simply analyzes what it is given. No hidden tricks, no special defect-detection mechanism behind it—it only evaluates the shape and size of the selected ROI components. In other words, you decide what your defects are. It could be pores, inclusions, thin walls from wall thickness analyses, or large deviations from nominal/actual comparisons.

"From Defect ROI" simply calculates the statistics of the defects.

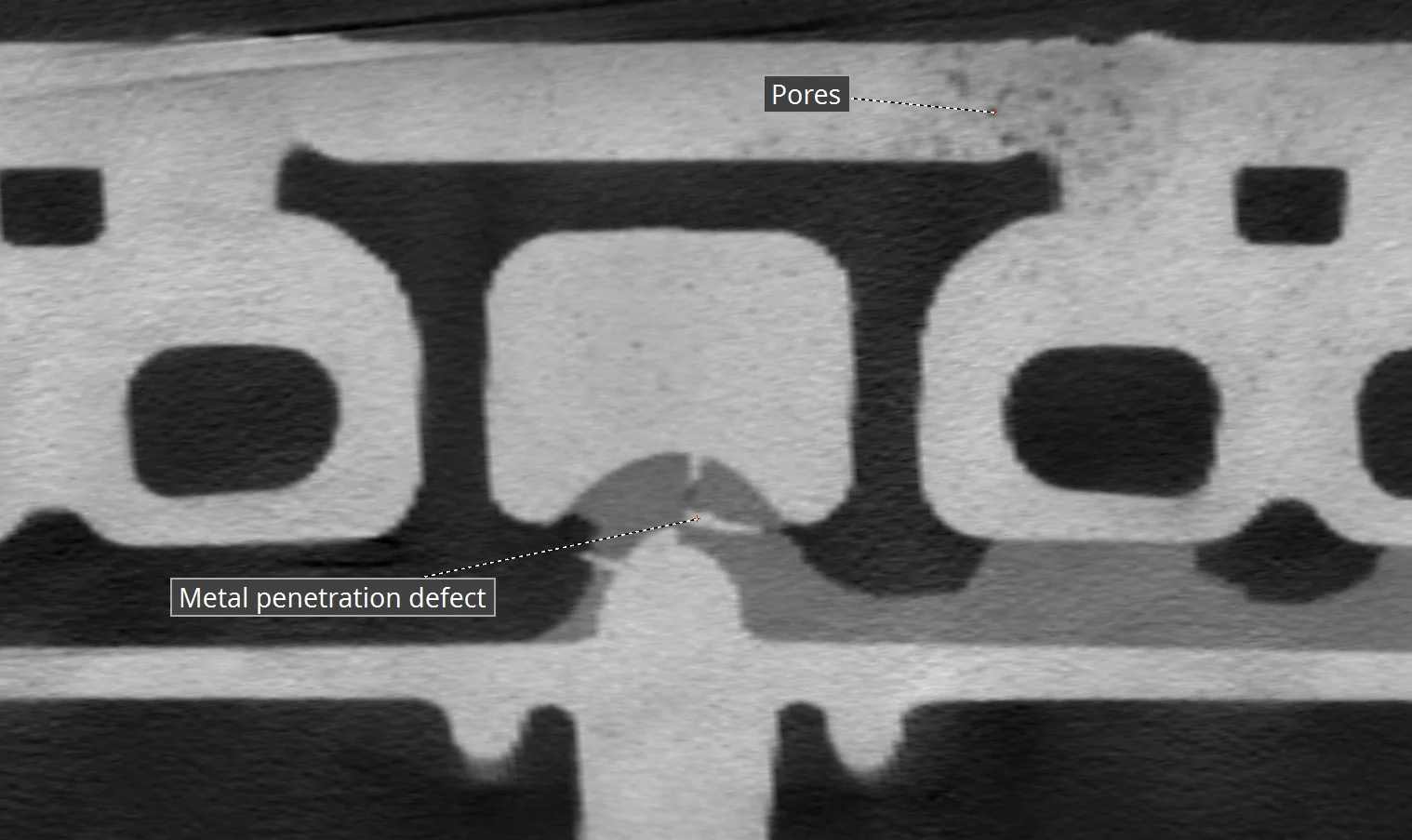

Combined view of voids from a porosity/inclusion analysis and a metal penetration defect due to a cracked sand core from a wall thickness analysis.

Ready to Learn More?

Users of VGSTUDIO MAX can find out more about porosity/inclusion analyses in the tutorials included in the software.

Got a Story?

If you have a VG Story to tell, let us know! Contact our Storyteller Team at: storytellers@volumegraphics.com. We look forward to hearing from you.