This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

What's New in VGMETROLOGY

Discover the Exciting New Capabilities of Version 3.3 (as of December 2019, Version 3.3.3)

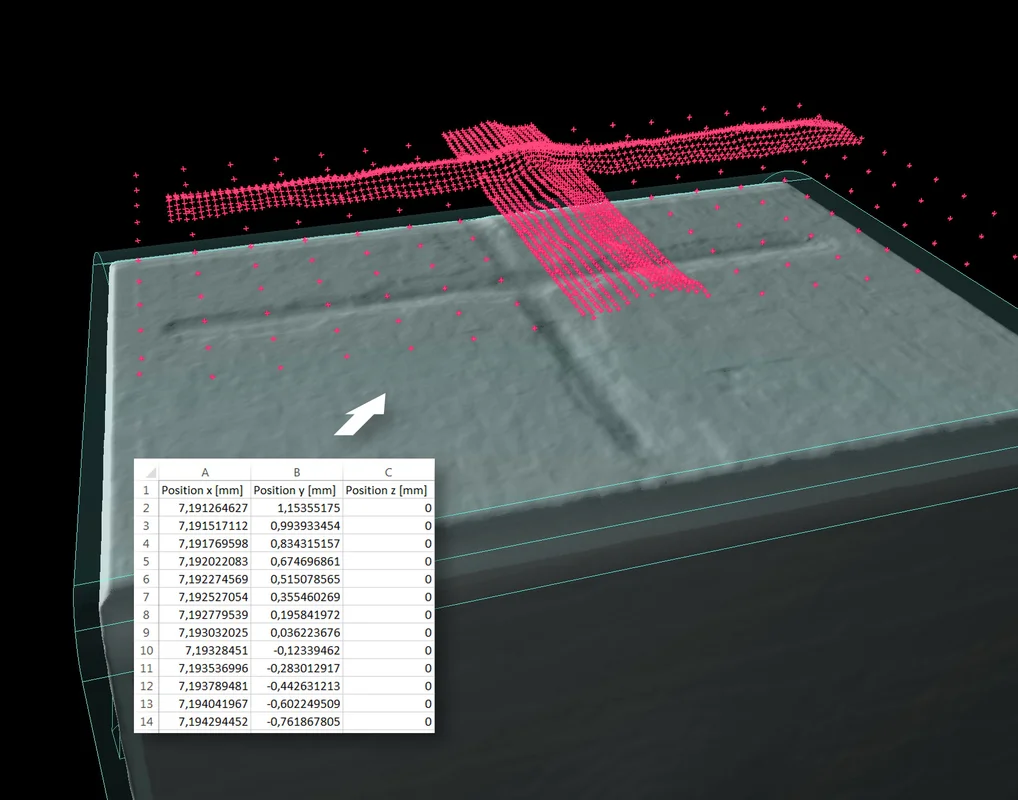

Import, Compensate, and Export Specific Points (New in 3.3.3)

The Manufacturing Geometry Correction Module now lets you import, compensate, and export specific points. By using specific points instead of arbitrary fit points, you can automatically update parametric constructions in CAD systems based on these specific points.

Refined User Interface

A new, more streamlined user interface in all applications is the most obvious change in version 3.3. A better visibility of symbols and texts makes any task in the software even more straightforward.

Performance Enhancements

When using version 3.3, you will immediately realize how much more responsive the application feels and how much faster some processes are. The performance enhancements affect everyday tasks such as the opening of very large .vgl files, rendering and navigation in 2D and 3D views, copy & paste actions in the Scene Tree, and autosaving.

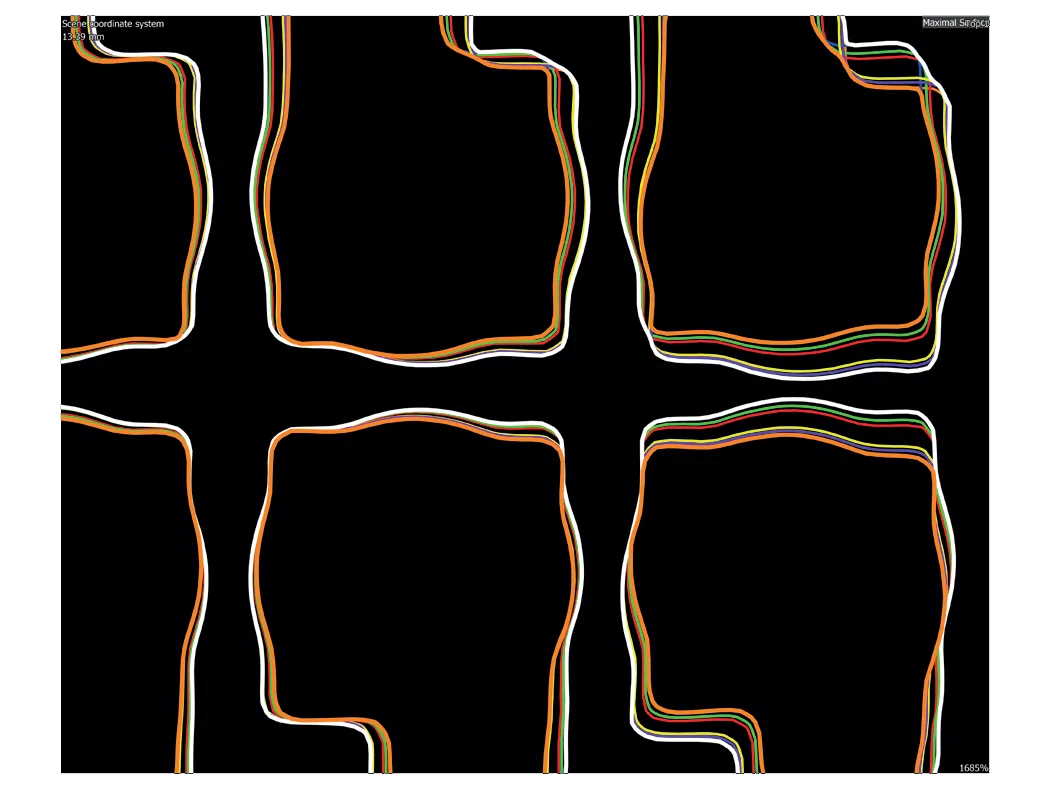

Extended Golden Surface Creation

The creation of golden surfaces (i.e., average surfaces) for multiple identical volume objects now includes the option for maximum and minimum material surfaces. It saves you time when tolerancing multiple identical parts, e.g., from a casting or injection molding tool with multiple identical nests, by tolerancing only the minimum and maximum surface. If these surfaces fulfill all tolerances, this also applies to the individual components.

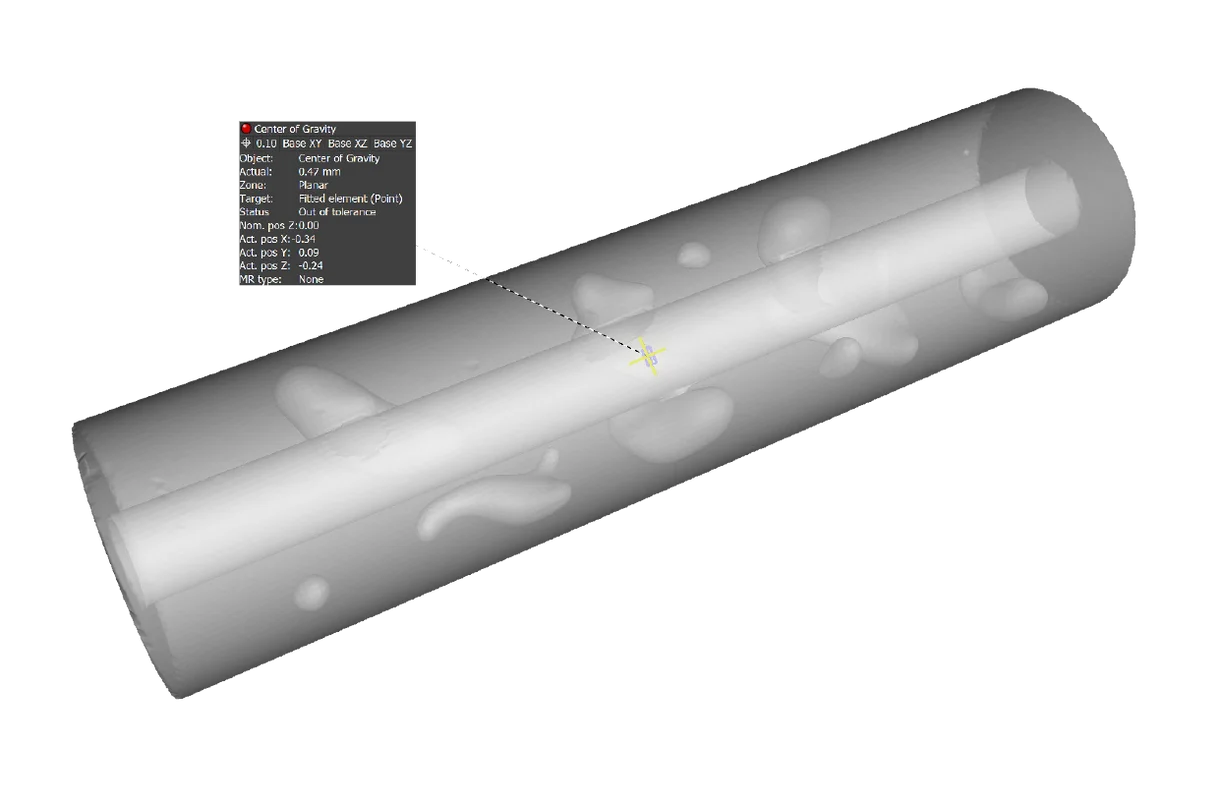

Centroid of ROIs

By calculating the centroid, i.e., the geometrical center of an ROI, you can reduce the time required for the assessment of potential mechanical imbalances, e.g., in rotating parts. The calculation can be automated via macros and the position of the resulting centroid point can be toleranced.

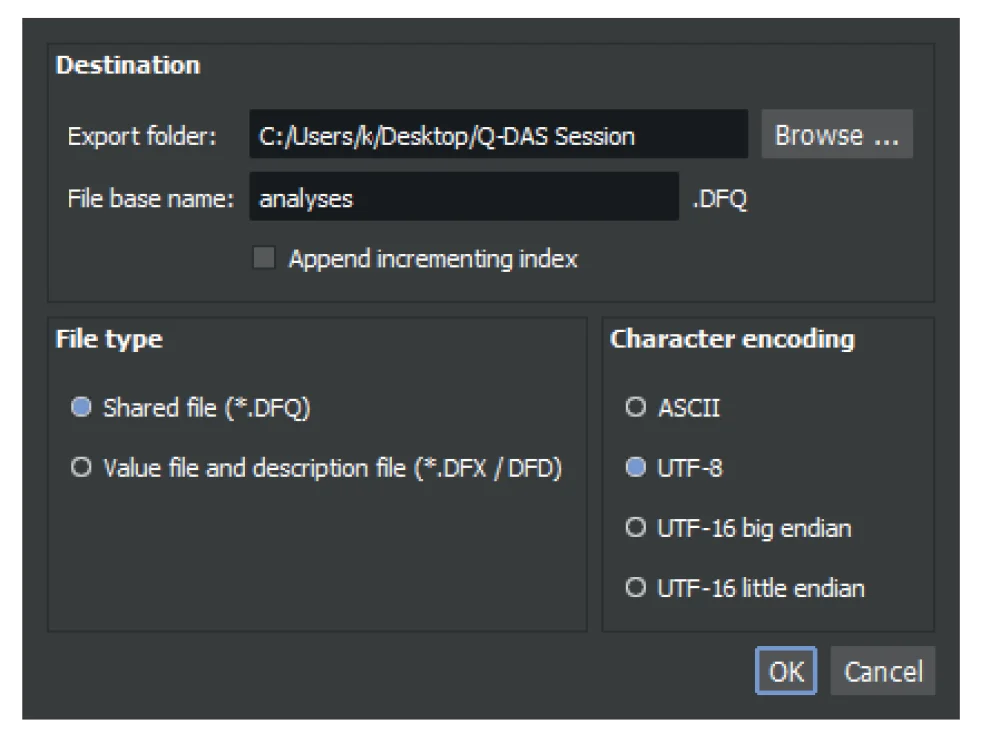

Q-DAS Export

To centrally store CT results in quality management or statistical process control software, you can now export the detailed results of dimensional measurements, position & form tolerancing, and the global results of analyses (nominal/actual comparison, wall thickness analysis, porosity/inclusion analysis, fiber composite material analysis) using the widely used Q-DAS data exchange format.

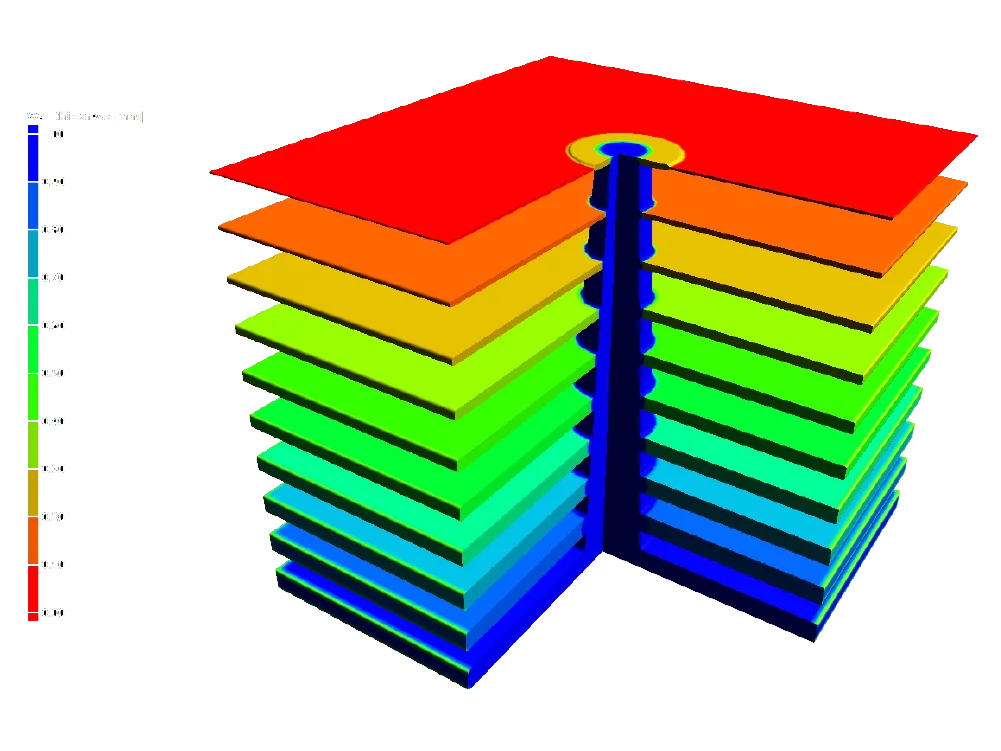

Wall Thickness Analysis Included in VGMETROLOGY

The Wall Thickness Analysis Module is now included in VGMETROLOGY and VGMETROLOGY ES at no extra charge, enabling you to localize insufficient or excessive wall thickness or gap width in cast, injection molded, or 3D printed components with complex internal geometries.

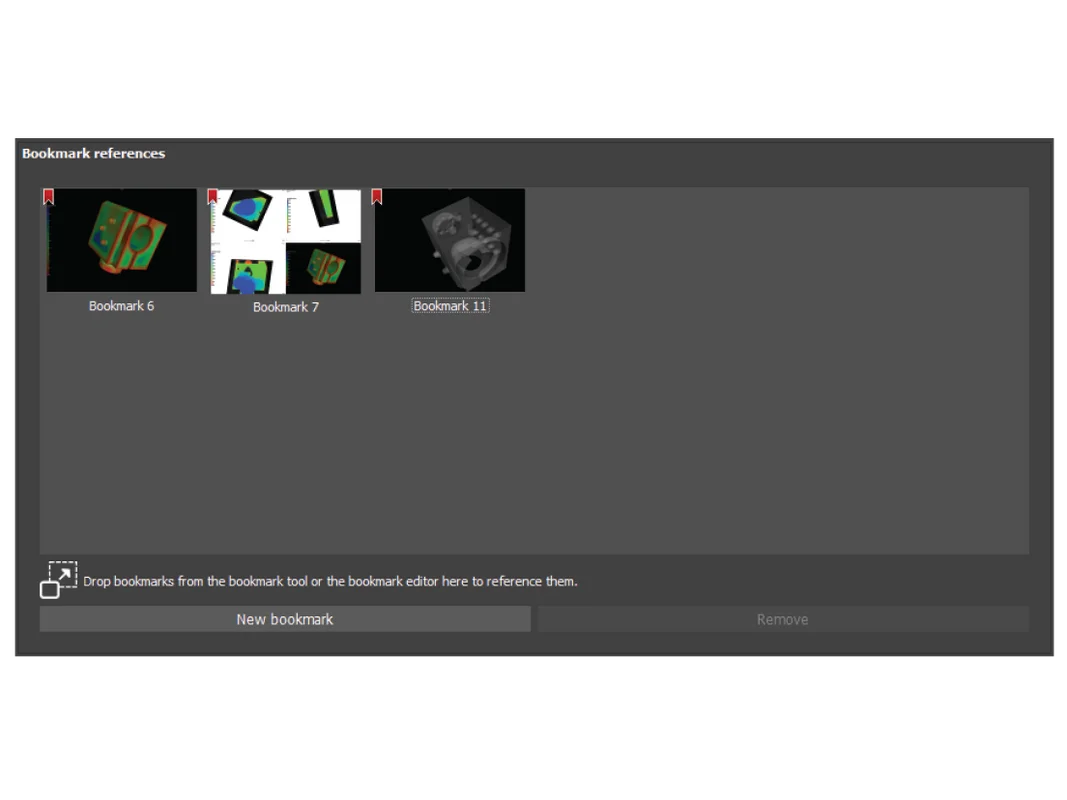

Reportable Bookmarks

Reportable bookmarks make creating reports of top-level objects and analyses in automation scenarios more flexible and highly reproducible. Bookmarks can now be referenced by volumes and other top-level objects, analyses, and measurement plans and are included in the .vgrf format as well as in the associated reports in Microsoft Excel (requires Microsoft Excel) and reports in the .pdf format. Reportable bookmarks offer a combination of high flexibility—because arbitrary 2D and 3D views can be stored as bookmarks—and high reproducibility for automated setups—because bookmarks can be stored as templates which can be used in automated workflows.

Continental Floating Licenses

If you are a company with multiple sites across one continent, you can now share licenses across one continent, increasing your capacity utilization and reducing license management effort. The new continental floating licenses are available for the Americas, EMEA (Europe, the Middle East, and Africa), and the Asia-Pacific region.

Local Floating Licenses

If you are a company with multiple users in one city who do not use the software full-time, you can now share licenses across one city increasing your capacity utilization and reducing license management effort. Compared to a dongle license, the new local floating license requires no effort to transport the dongle and avoids the risk of losing it. Compared to legacy floating licenses, local floating licenses allow parallel instances, different functionality of each license, and offline borrowing for up to 7 days.

Meta Information Dependent Input in Jobs

The input data (analyses, references objects) of job steps can now depend on meta information. When inspecting automatically, e.g., injection molded or cast components, the software can apply the right reference objects and analyses for the part depending on the meta information, such as the cavity number.

Visualization and Navigation

- Cylindrical and conical clipping objects allow for faster visualization of rotationally symmetric objects, such as axles, batteries, or pipings. (new in 3.3.1)

- Improved performance of rendering and navigation in 2D and 3D views for a more fluent and immediate response, e.g., when zooming, slice scrolling, rotating, or moving an object.

- Improved interactiveness and responsiveness upon selections or copy & paste actions in the Scene Tree, creation of annotations, and selections in tables when working with projects with many objects in the Scene Tree.

File I/O

- You can now use the shortcut "Ctrl + Shift + G" to save relevant view content as an image while manually inspecting a part. This saves time and reduces interruptions in your inspection workflow. (new in 3.3.3)

- Faster saving of large .vgl files—in addition to faster loading already introduced with version 3.3.0. This saves time when handling large .vgl files (e.g., when a project contains large measurement templates with a large number of geometry elements and features, especially freeform tolerances, or complex analyses with a large number of results). (new 3.3.1)

- Faster autosave, resulting in about 10 times faster automatic file saving for large .vgl files.

- Import CAD, mesh, and point cloud files by simply dragging and dropping the file into the scene.

Macros

- The creation of CAD files from geometry elements is now macro recordable.

- The export of transformations is now macro recordable.

Geometry Elements

- New option to create CAD elements from lines, circles, freeform lines, and freeform surfaces.

Datum Systems

- Datums for profile tolerances are now independent of the storage system of the toleranced object.

Registration

- Improved usability of registration thanks to unified dialogs for all (registration) methods.

- The locked state (unlocked, locked or hard-locked) of created top-level objects (e.g., meshes, CAD objects or extracted ROIs) is now derived from their source objects, which helps you avoid errors in automated workflows.

Dimensional Tolerancing

- Project-specific nominal and tolerance values of geometric dimensions can now be imported as a .csv table and assigned to the features based on the feature names. This saves time compared to the manual entry of the tolerance and nominal values, since the tables are typically available from the design engineer or a ballooning software. (new in 3.3.1)

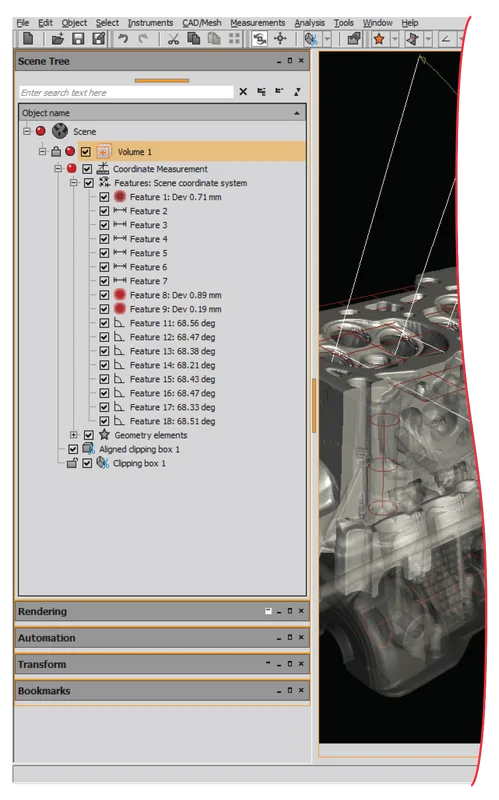

Geometric Tolerancing

- When tolerancing freeform surfaces, deviations between nominal and actual surface profiles can now be visualized in 2D and 3D views via a nominal/actual comparison, allowing for a detailed interpretation of the tolerancing result. The positions of the minimum and maximum deviations can be copied into the nominal/ actual comparison and displayed as annotations.

Manufacturing Geometry Correction

- In the Manufacturing Geometry Correction Module, a new export of compensated points provides an alternative to the creation and export of compensated CAD surfaces for very complex surface shapes.

All Analyses

- Columns of an analysis table can now be hidden or shown with one click, giving you an easy and convenient way to display only the information of interest and reduce the amount of reported data in the standard reporting (HTML, PDF). (new in 3.3.3)

- With just one click, you can now update even a high number of analyses for an object, which is enormously time-saving.

Reporting and Traceability

- The object meta information now includes the fields production time and cavity number, improving traceability and filtering options, e.g., in reports or when exporting it in the Q-DAS data exchange format.

- You can now display meta information in text overlays in 2D and 3D windows, both the built-in meta information fields and custom fields from the component, the scan, or the scanner manufacturer section. This increases the traceability of screenshots and, when viewing several similar scans in one scene, better indicates which scan is currently displayed and analyzed.

- To analyze multiple files in the same way, VGinLINE jobs in VGSTUDIO MAX now support multiple input files which will be processed in sequence. This way, batch playback—which previously only worked with macros—is now also available for the more powerful VGinLINE jobs in VGSTUDIO MAX. Results can either be stored in the same folder or individual subfolders.

Volume Graphics GmbH

Speyerer Straße 4-6

69115 Heidelberg

Germany

Phone: +49 6221 73920 60

Fax: +49 6221 73920 88

Sales enquiries:

sales@volumegraphics.com

Modifications and errors reserved.