Skeleton is a winter sliding sport in which a single rider rides down a frozen track in a small sled while lying face down and head-first, mere inches from the ice. Despite the name, skeleton goes far beyond the bare bones of racing, especially since it became an Olympic sport in 2002. But true to its name, the sport does a number on one's body, especially the neck and shoulders.

Skeleton Racing

"Skeleton" likely refers to the sled's appearance, but it is brutal to the body. Because the helmet and shoulders produce most of the air resistance, athletes tuck their heads down while arching their eyesight upward to see where they are going. This is important, because there is no steering mechanism; the athlete shifts their body weight using their knees and shoulders to alter the center of gravity.

Turning is the most physically brutal part of the sport. A sharp turn produces intense pressure known as g-forces, short for gravitational force, of up to five times the normal amount (for comparison, a space shuttle launch "only" produces 3 g). For a split moment, the rider's head weighs as much as a few bowling balls, and holding it slightly upward, away from the ice, becomes a matter of life and death.

The stress from these turns quickly wears down the neck muscles and wreaks havoc on the shoulders.

It may look like the athlete is "chilling" on the ice, but skeleton racing places tremendous stress on the neck and shoulders

Still, the rush of up to 140 kph (87 mph), just inches above the ice, is what awaits Czech skeleton racer Anna Fernstädtová in the upcoming Olympics in Beijing. To go for gold, she needed the absolute best way to protect her head, neck, and shoulders. This is where CT scanning and 3D printing come to the rescue.

The Anatomy of a Skeleton (Helmet)

Because of the potential damage to one's neck and shoulders, skeleton athletes wear special racing helmets that must be (1) strong enough to protect the rider's skull upon impact, and (2) light enough to not add to the pressure at 5G speeds. The helmet covers the face and chin to prevent them from touching the ice.

By nature, the skeleton helmet requires a robust shell and shock-absorbing inner material. Often, designs incorporate thick padding that may perform poorly when compared to more complex, flexible materials. But how can they design a custom helmet that is both lightweight and heavy duty?

The answer is simple: Kevlar. And lattice structures.

Lattice Structures

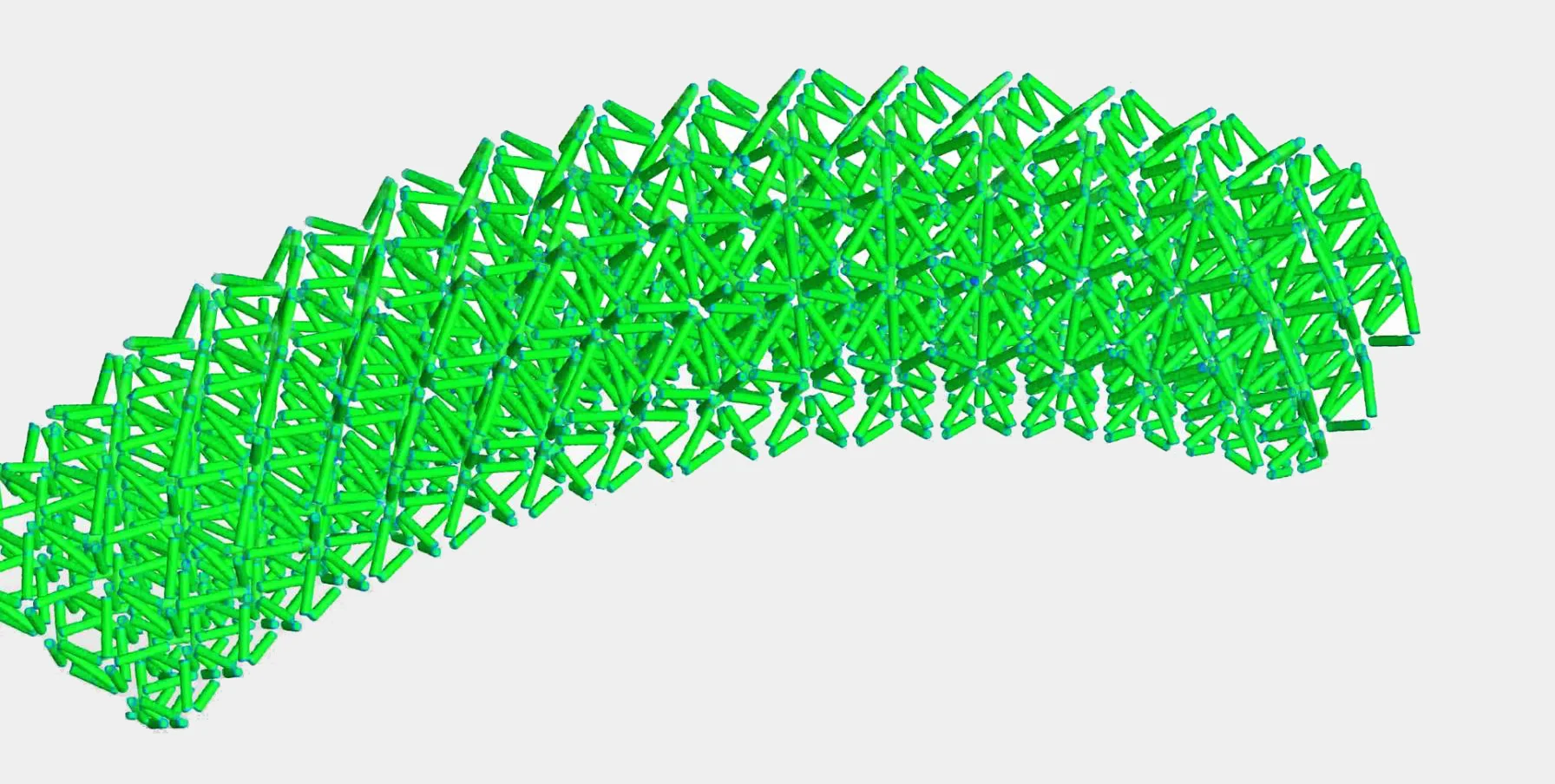

Lattice structures are interlocked materials that can be precisely configured and 3D printed. The configurability of their design combined with a variety of possible materials allows them to reach high-impact performance and flexibility, which makes lattices perfect for customized fits and wearing comfort. Because the lattices themselves are 3D printed, this method is also cost-efficient, as the need for expensive manufacturing tools is eliminated.

3D-printed segment of a lattice structure (credit: Vagus, One3D)

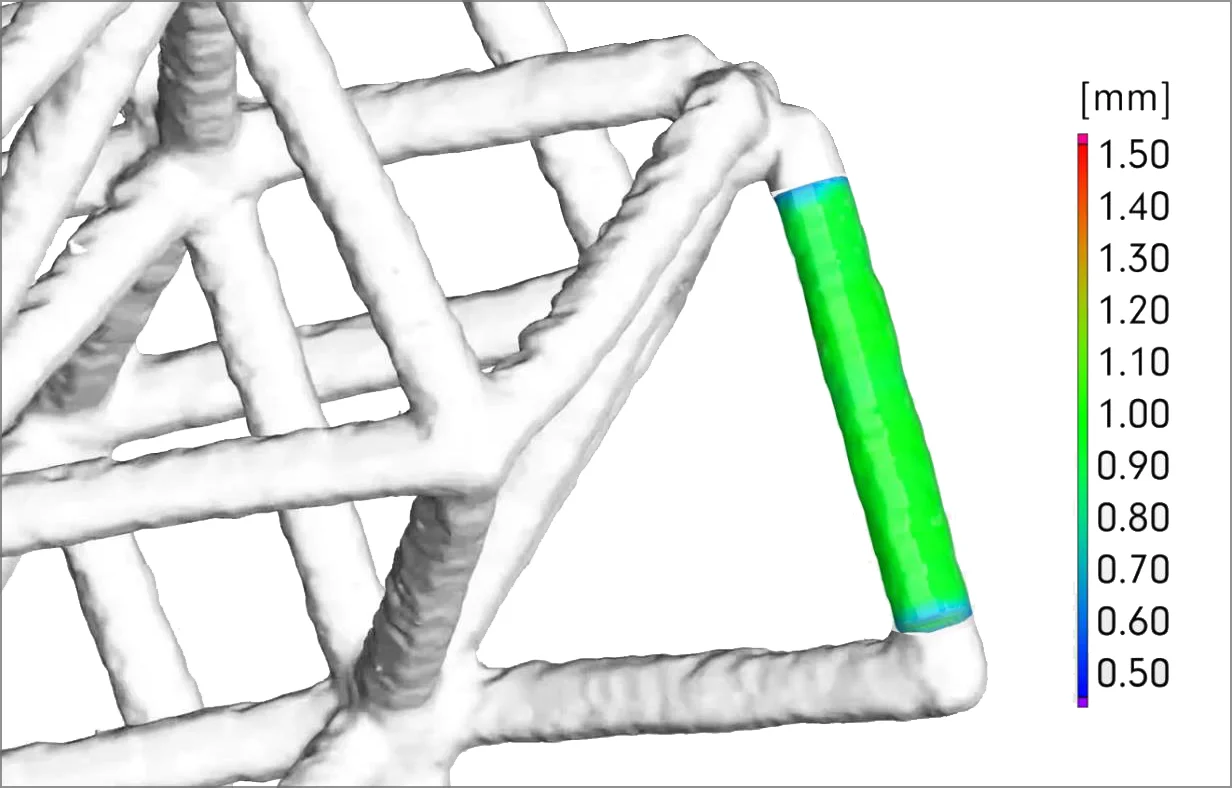

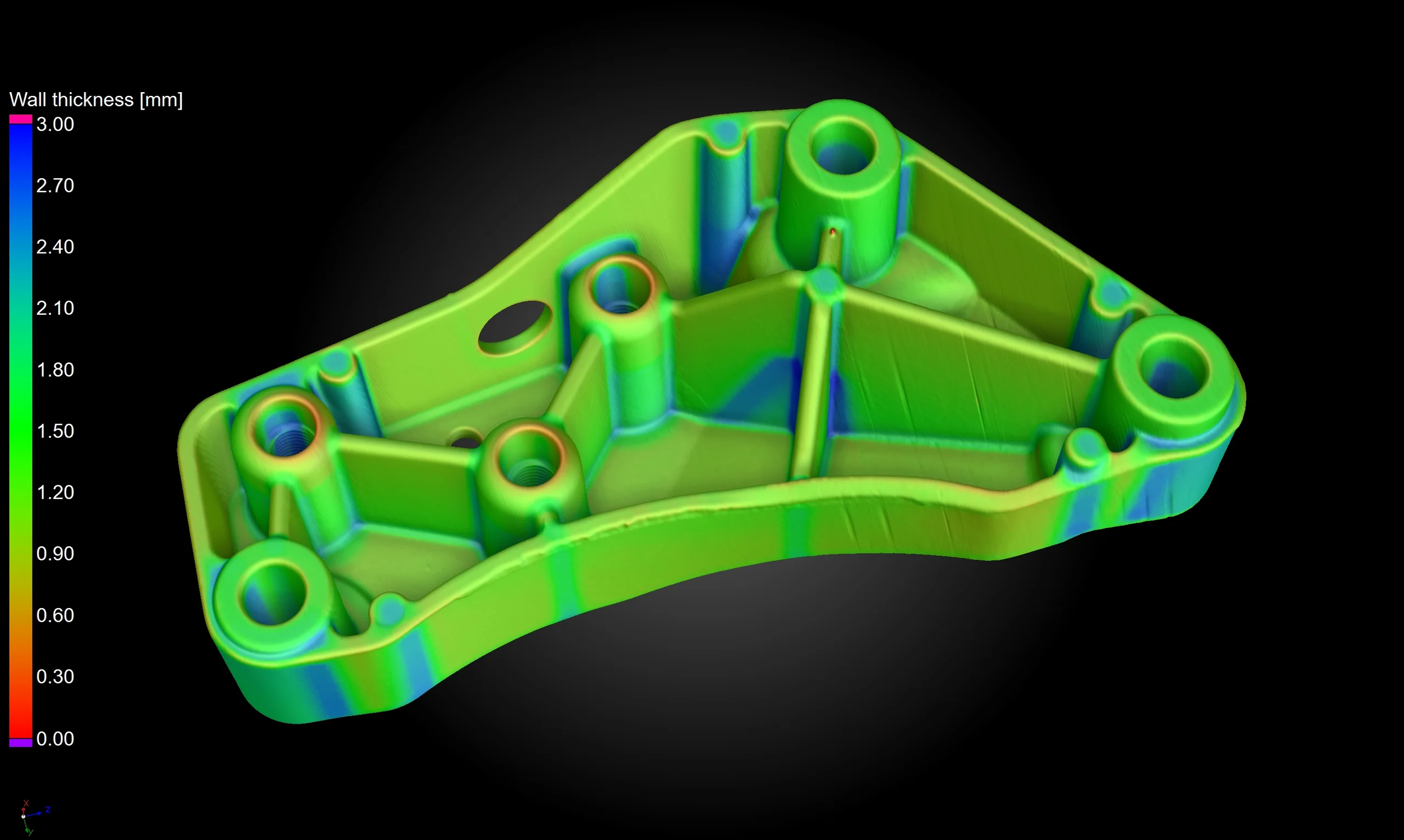

A closer look at the wall thickness analysis on a single strut of the lattice structure

The configurability and flexibility of lattices led to a brilliant idea, and collaboration between sports technology, 3D printing, and materials science.

Going for Gold

Designing the perfect Olympic helmet for skeleton racing led to the unique collaboration between Vagus, a producer of Kevlar helmets and other sporting equipment, One3D, additive production and post-processing specialists, and CEITEC, a leading research facility in advanced materials.

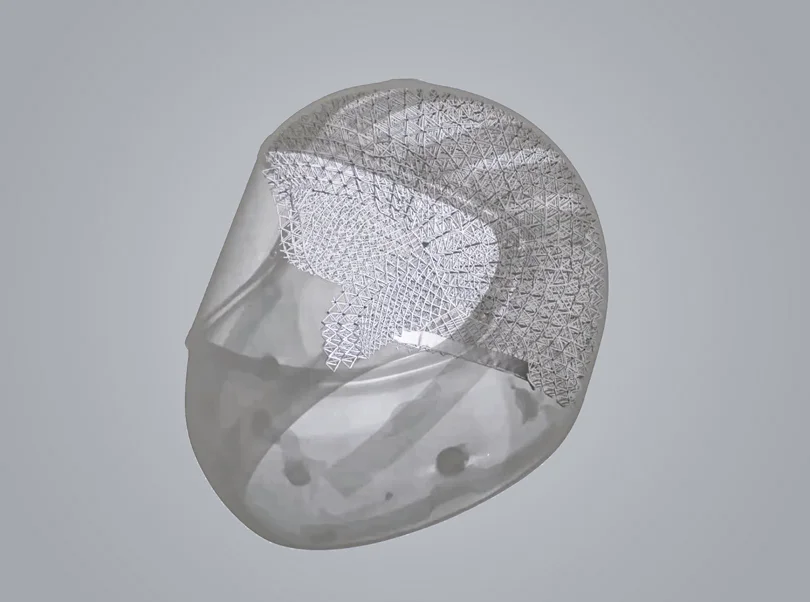

To ensure maximum comfort and high-precision customization, they scanned Anna's head and created the inner lining based on the 3D data.

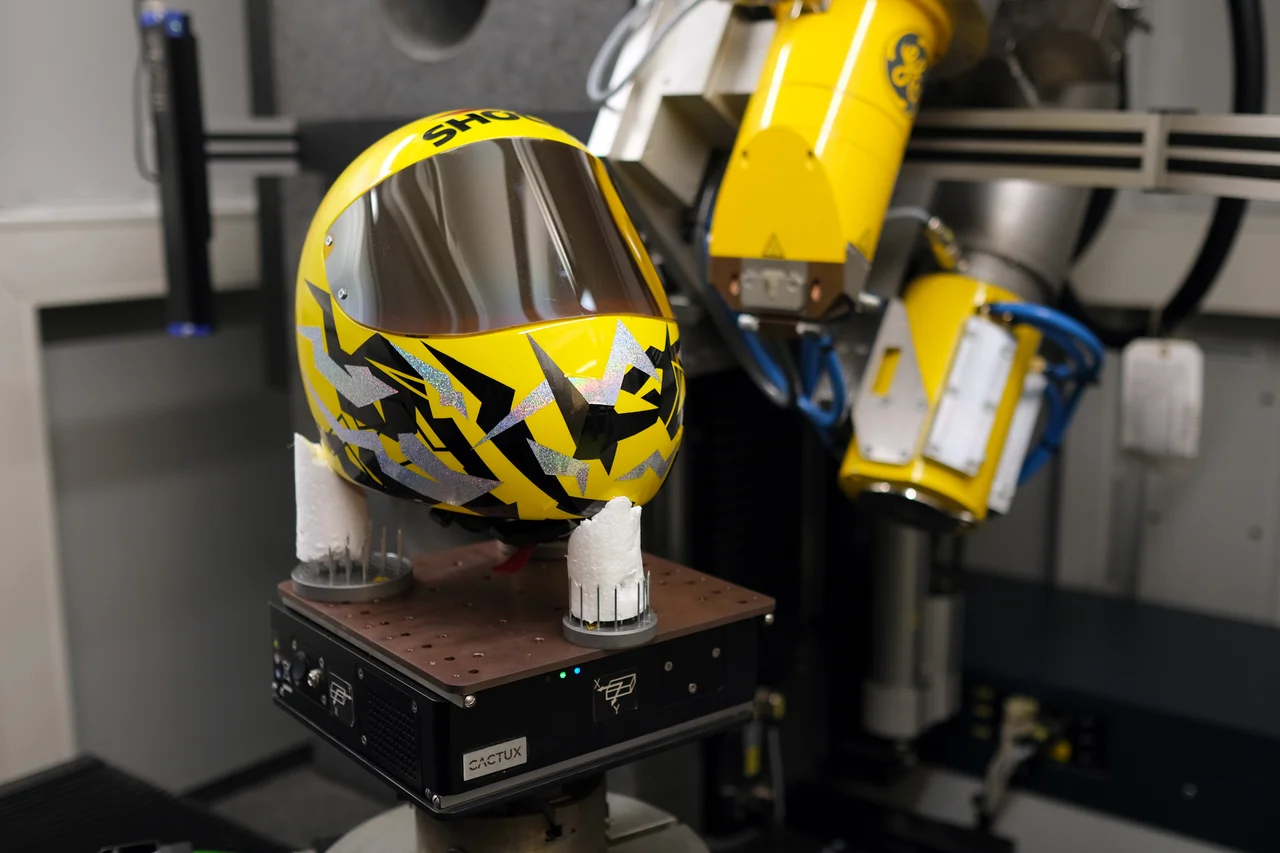

3D scanning Anna's head (credit: Vagus, One3D)

The lattice structures were 3D printed using Nylon 12, which is known for its impact strength and ability to flex without breaking. The balance between lattice structure and stiffness ensured maximum safety in the helmet.

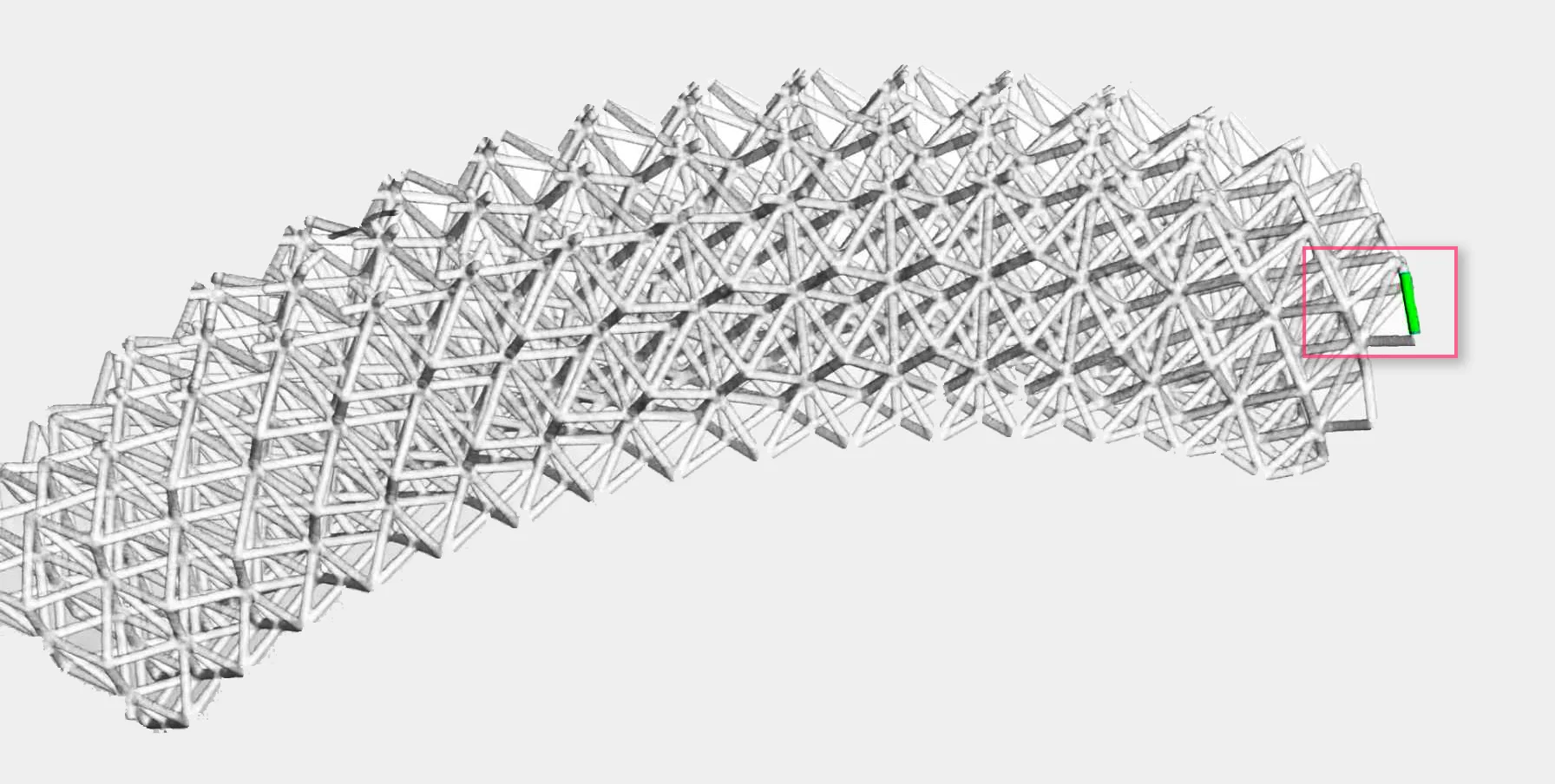

Based on the 3D data, the lattice structures were virtually adjusted to the athlete's head

The outer shell, however, is made of Kevlar and sanded, polished, and painted.

Building the physical helmet based on 3D data (credit: Vagus, One3D)

The polished skeleton helmet, ready for CT scanning (credit: CTLAB CEITEC)

Physically, the helmet was tested using a 5-kg crash dummy head falling from a height of two meters. Now it was time to test it virtually.

VG Solution

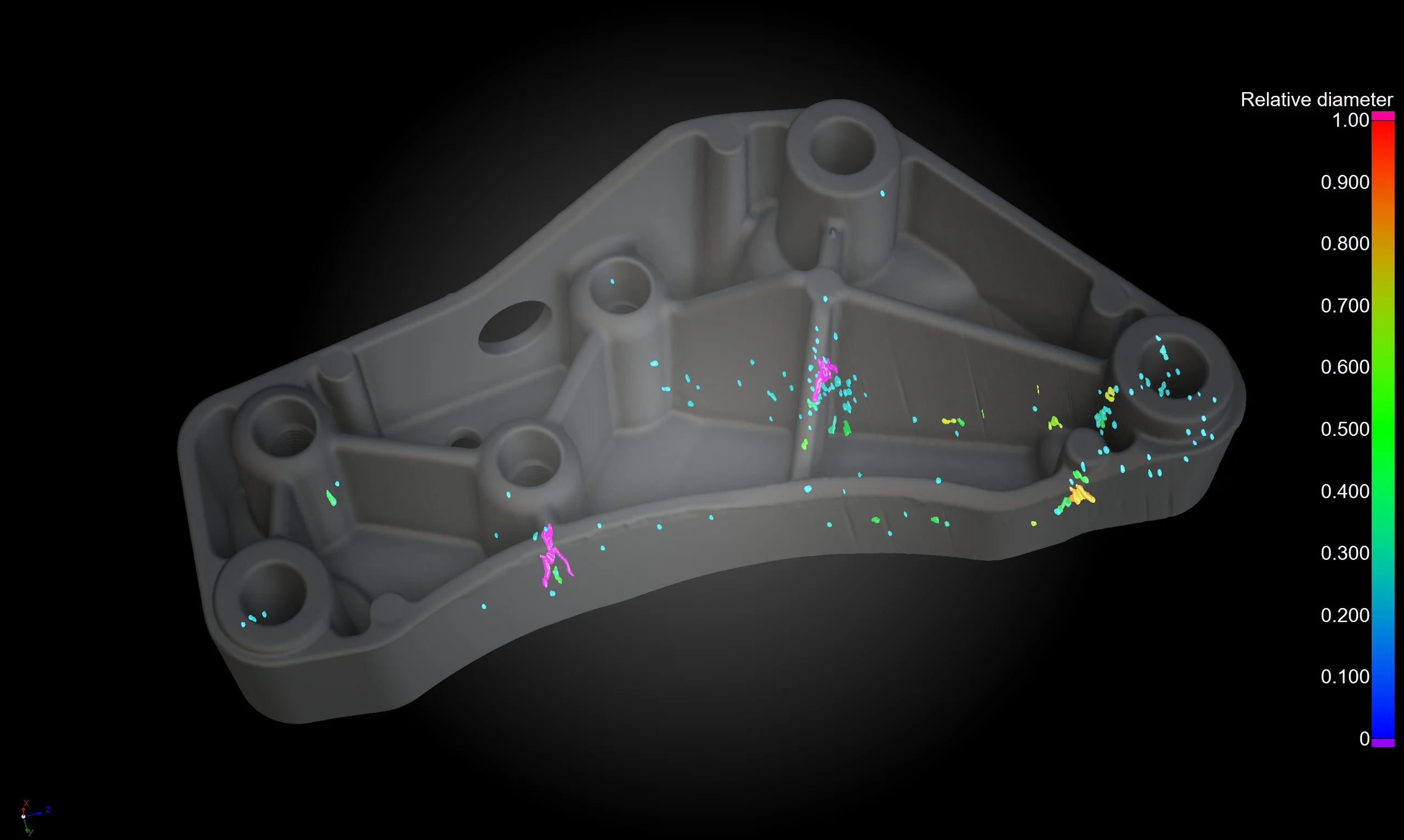

Technology used in 3D printing can produce pores, which, given the thin, precise size of the struts in the lattice structure, are especially significant. CT technology as non-destructive testing is perfect for such fine, complex structures, and we can use porosity/inclusion analysis in VGSTUDIO MAX to inspect each strut for pores.

The thickness of the struts should be consistent, as variations increase the likelihood of damage. A wall thickness analysis would give us global information on the range of these deviations. It also allows us to tolerate the thickness and place annotations at critical points.

Did You Know? PIA + Wall Thickness

There is an option to consider wall thickness analysis as part of a porosity/inclusion analysis. This would calculate the relative pore diameter based on the results of the wall thickness analysis. In other words, it evaluates whether the pore is significant in relation to the thickness of the walls.

In the case of the lattice structures in the helmet, this gives us invaluable information on which pores have the most impact on the stability of the struts.

Considering wall thickness analysis as part of a porosity/inclusion analysis

Go Big or Go Home!

In the end, CEITEC, Vagus, and One3D were able to create the perfect Olympic helmet based on 3D data of the skeleton athlete's head. This was a great example of how 3D technology, sport safety, and materials science can be combined to go for gold.

Good luck (and stay safe) to all the athletes competing!

Go for gold!

Ready to Learn More?

Users of VGSTUDIO MAX can find out more about porosity/inclusion analysis and wall thickness analysis in the tutorials included in the software.

Got a Story?

If you have a VG Story to tell, let us know! Contact our Storyteller Team at: storytellers@volumegraphics.com. We look forward to hearing from you.