This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

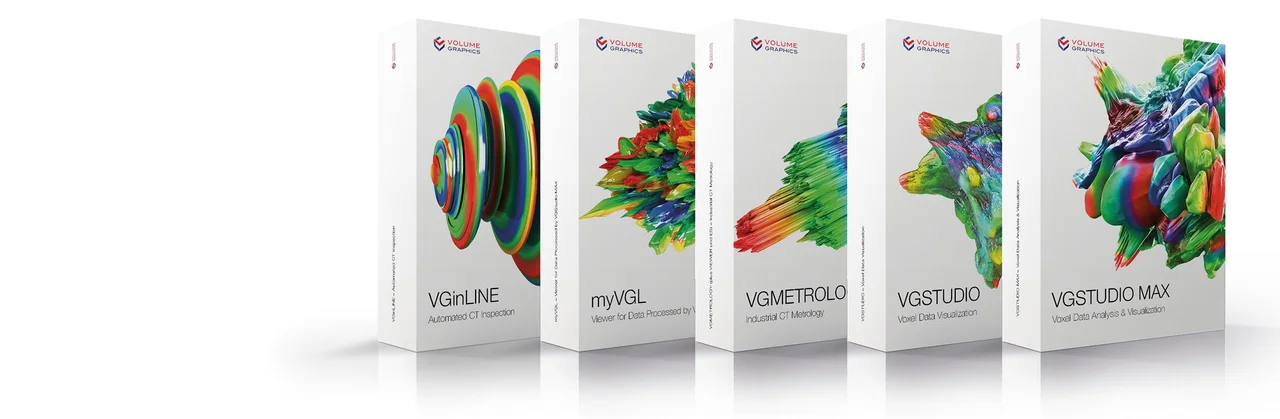

With the Volume Graphics product family, all kinds of analyses and visualizations can be carried out directly on data from industrial computed tomography (CT).

Version 3.4 Is Here

Volume Graphics introduces the next version of its product family for the analysis and visualization of industrial computed tomography (CT) data: Version 3.4 of VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, and VGinLINE. Among the innovations are a new Reverse Engineering Module, which converts CT scans into CAD models, a new visualization option for deviations of geometric tolerances, and subvoxel-accurate defect detection.

An overview of the major new features in version 3.4:

- Reverse Engineering Module to easily convert CT scans into CAD models for use in CAD systems with a new auto surface function.

- New visualization option for deviations of geometric tolerances to answer questions such as: Where exactly are the highest deviations located? How are the deviations distributed on a surface? Which areas of the surface were actually evaluated?

- Subvoxel-accurate defect detection with VGEasyPore to differentiate between gas pores and shrinkage cavities based on the sphericity and compactness of defects by capturing the shape of defects with subvoxel accuracy.

- Digital Volume Correlation Module to simply and intuitively quantify displacements between an initial and a deformed volume, e.g., from in-situ tensile tests.

- Stress tensor export to export stress fields calculated using the VGSTUDIO MAX Structural Mechanics Simulation Module, e.g., for fatigue analysis, by mapping the stress tensor components onto a volume mesh and exporting them in a .csv format.

- New, more intuitive Tool Dock that reduces the mouse travel needed to navigate to the next tool.

- Support of 4K displays for a crisper, sharper, and scalable graphical user interface of all applications on 4K displays.

- Parallel task processing by VGinLINE WORKER to significantly speed up throughput and remove downtime.

Discover all new capabilities in detail on our "What's New" pages for VGSTUDIO MAX 3.4, VGSTUDIO 3.4, VGMETROLOGY 3.4, and VGinLINE 3.4.

Availability of the New Version

VGSTUDIO MAX 3.4, VGSTUDIO 3.4, VGMETROLOGY 3.4, and VGinLINE 3.4 are available now. Volume Graphics is happy to provide quotes upon request.

Volume Graphics offers free evaluation versions of VGSTUDIO MAX 3.4, VGSTUDIO 3.4, and VGMETROLOGY 3.4 for temporary use.

myVGL 3.4 is available free of charge and can be requested on the Volume Graphics website.

About Volume Graphics and Hexagon

Volume Graphics GmbH has been developing software for non-destructive testing based on industrial computed tomography (CT) for over 20 years. Customers around the world, e.g., from the automotive, aerospace, and electronics industries, use Volume Graphics software for quality assurance in product development and production. In addition to its headquarters in Heidelberg, the company has branches in the USA, Japan, Singapore, and China. Learn more at www.volumegraphics.com and follow us @volume_graphics.

Since 2020, Volume Graphics has been part of Hexagon. Hexagon is a global leader in sensor, software and autonomous solutions. We are putting data to work to boost efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications. Our technologies are shaping urban and production ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 21,000 employees in 50 countries and net sales of approximately 3.9bn EUR. Learn more at hexagon.com and follow us @HexagonAB.