This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

Volume Graphics at Formnext 2021

Quality Control in Additive Manufacturing

Get Full Control from Lab to Fab

Stop By the Hexagon Booth in Hall 12.0, Booth E69 for a Live Demo during Formnext 2021

Formnext 2021: November 16–19, 2021, Frankfurt am Main, Germany

When you inspect safety-relevant components, every little detail counts. From powder to printed part, from lab to fab—Volume Graphics software gives you the insights to constantly push the quality boundaries of your additively manufactured parts and establish efficient workflows. The software runs on data provided by the latest CT technology.

Volume Graphics software enables you to identify the most important 3D printing defects, whether from the raw material or the post-processed end product. No matter how complex the shape might be, Volume Graphics enables your metrology department to sign off on processes and accurately inspect your 3D-printed parts.

Request a Free Ticket

Hexagon has reserved a limited number of free tickets for customers. Head over to Hexagon's website and fill out the form to request your ticket:

Please note: Formnext 2021 will be held as on-site physical event in Frankfurt using the German 2G rule (for those vaccinated and recovered).

Your Comprehensive Toolbox

Measure, Inspect, and Simulate—All with One Software

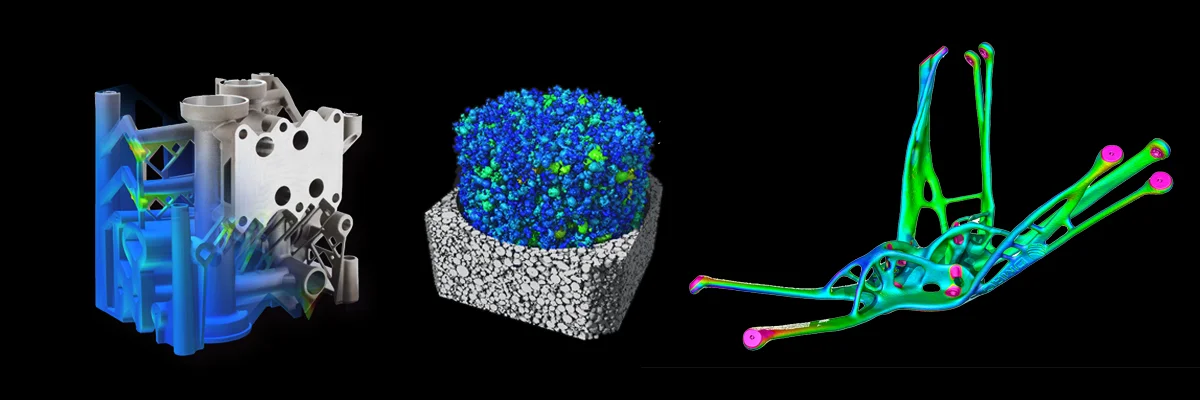

VGSTUDIO MAX is your tool for identifying the most important 3D printing defects—from raw material to the post-processed end product. Perform powder and meltpool data analyses, take dimensional measurements of all surfaces—even if they are inside your additively manufactured part—and find defects of all shapes and sizes.

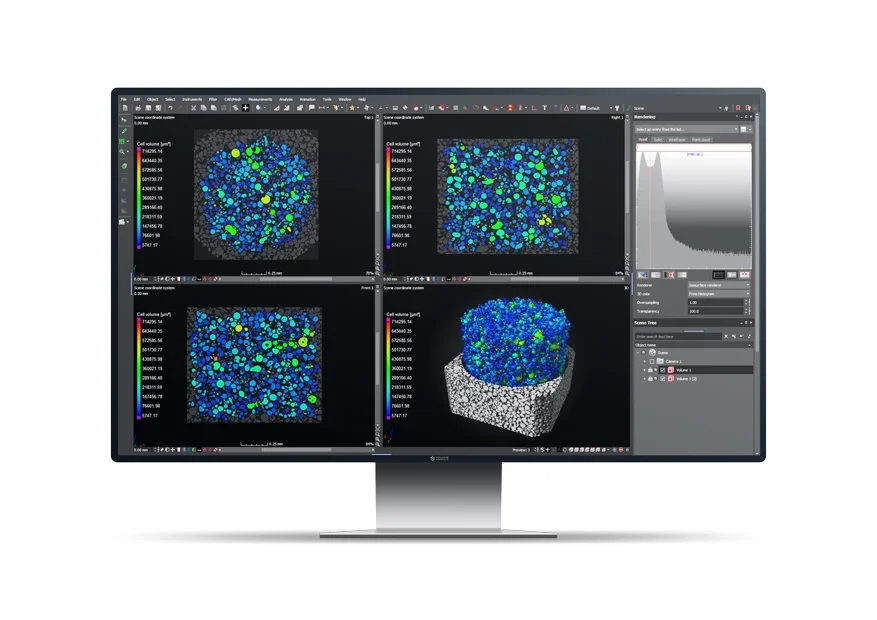

Powder Analyses

With VGSTUDIO MAX, you can analyze grain contaminations, trapped air, grain sizes, and shapes—automatically for tens of thousands of particles.

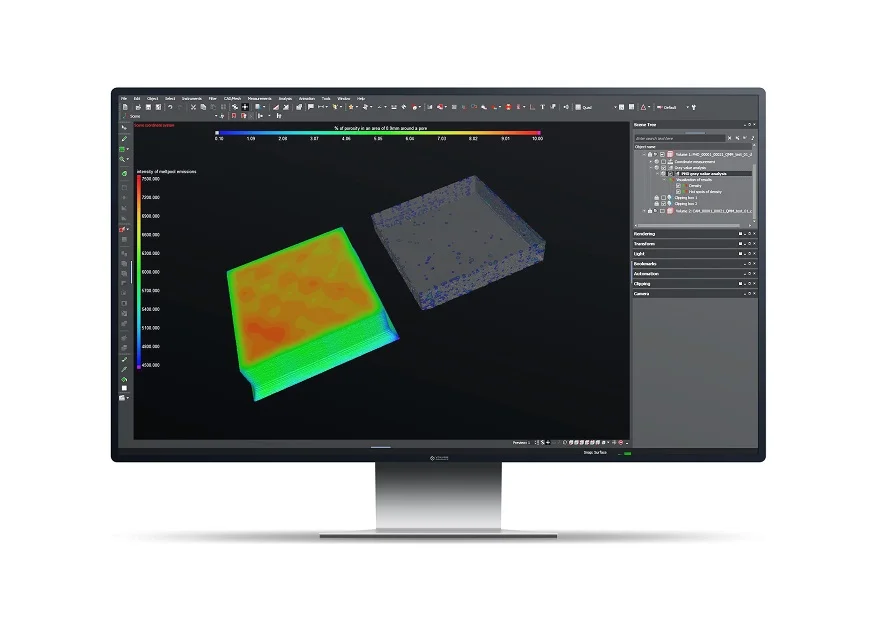

Meltpool Analysis

With VGSTUDIO MAX, you can 3D visualize the images generated by your additive manufacturing system's meltpool monitoring, analyze it, and compare it to the part’s CT data.

Dimensional Measurements

VGSTUDIO MAX gives you a full suite of measurement tools ranging from complex alignments to customizable measurement reports.

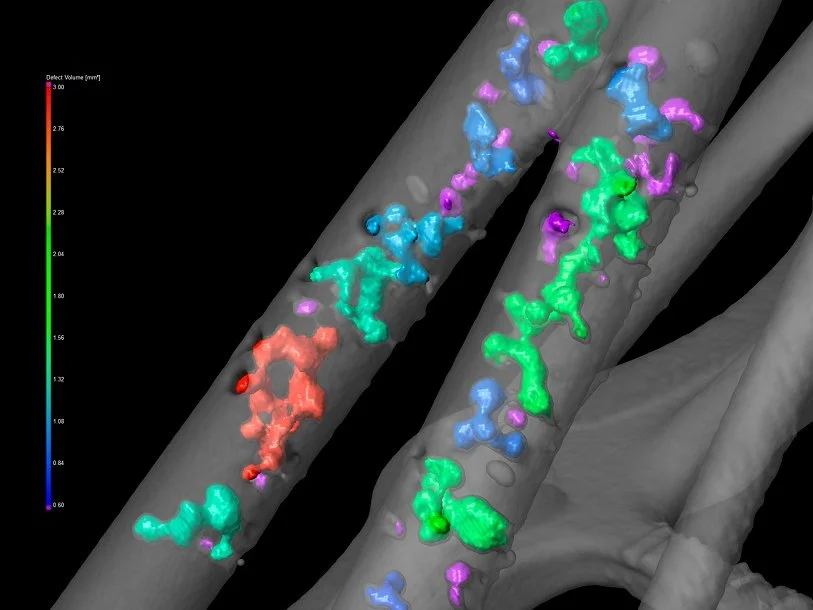

Porosity and Defect Inspection

With VGSTUDIO MAX, you can identify individual voids and inclusions and determine their sizes and shapes.

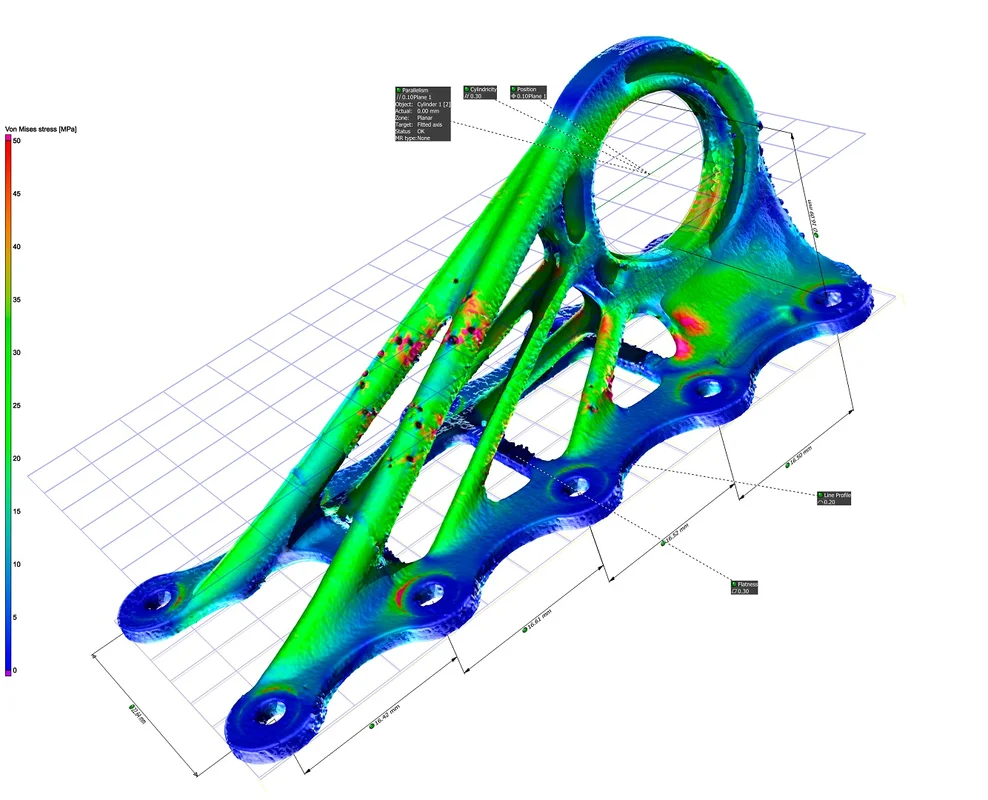

Structural Mechanics Simulation

VGSTUDIO MAX enables you to perform structural mechanics simulation (SMS) directly on CT scans.

Volume Meshing

For simulation in third party software, high-quality tetrahedral volume meshes representing the actual geometries and internal defects of the printed parts can be generated.

Why CT?

The Most Reliable Technology for 3D Inspection

Additively manufactured products need to be thoroughly inspected to be certified for high-risk use cases. Computed tomography (CT) is the most reliable technology for identifying 3D printing defects and enabling the best possible 3D printing quality.

Because CT reconstruction produces a complete representation of a component in 3D from a large number of 2D X-ray images, CT allows the user to draw conclusions on the external and internal structures of a component and its material properties. Thus, CT can answer more complex questions than, for example, tactile or optical inspection methods.

With its fully integrated CT reconstruction function, Volume Graphics offers a seamless connection to the comprehensive analysis and measurement functions of its software.

Moreover, the software works equally well with different CT systems from different manufacturers. Most major CT system providers sell Volume Graphics software together with their hardware. In addition, we rely on a worldwide network of distributors to serve our customers around the globe.

Stay Informed

Subscribe or follow Volume Graphics to stay up to date on all industrial CT news: