This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

EUROGUSS 2022

Hall 8, Booth 8-212

25 Years of Insights—Get Full Control from Mold to Part at Booth 8-212

At EUROGUSS (June 8–10, 2022, Nuremberg, Germany), the international trade fair for die casting, Volume Graphics will show you the latest versions of VGSTUDIO MAX, VGSTUDIO, VGMETROLOGY, and VGinLINE—your software of choice for analyzing and visualizing industrial computed tomography (CT) data. Visit Volume Graphics at booth 8-212 and see for yourself how you can benefit from 25 years of experience in CT-based quality assurance.

From mold to cast part, from part design to inspection—Volume Graphics software gives you the insights to constantly push the quality boundaries of your cast parts and establish efficient workflows. We enable you to identify the most important imperfections in castings, whether caused by the mold or the casting process—quickly, easily, and with incredible accuracy. No matter how complex the shape might be, Volume Graphics allows you to sign off on processes and accurately inspect your cast parts.

Attend the Free Workshop on Casting Analysis with VGSTUDIO MAX by Our Casting Expert Andreas Harborth

Save 25% on VGMETROLOGY ES + Manufacturing Geometry Correction

Want to optimize your tools and 3D-printing geometries using the comprehensive data of CT? Read more about the special anniversary discount on VGMETROLOGY ES and the Manufacturing Geometry Correction module.

Get on the CT Fast Track with Our Customer Success Package

With our new Customer Success Package, we want to help you get the most out of industrial CT and Volume Graphics software—from initial implementation of CT to fine-tuning workflows. Read more about our new Customer Success Package and the special 25th-anniversary price.

Version 2022.1 of Your Comprehensive Toolbox for Quality Assurance

Volume Graphics offers the tools necessary for CT-based quality assurance across the life cycle of cast components, from designing the part to automatically inspecting it: geometric dimensioning and tolerancing, mold cavity correction, wall thickness analysis, nominal/actual comparison, porosity and inclusion analysis, virtual machining, and stress simulation.

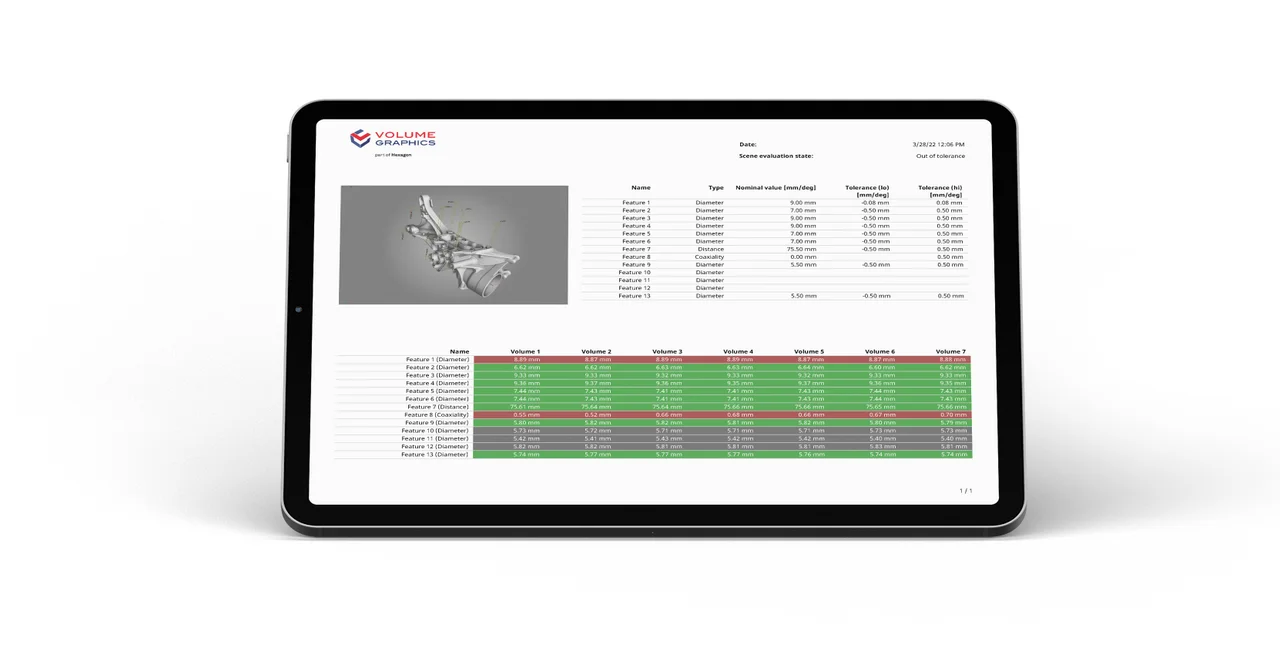

Dimensional Measurements

Dimensional deviations are a typical problem of all manufactured parts, including castings. VGSTUDIO MAX allows you to fit geometry elements and create geometric dimensions and tolerances, giving you all the functionality of a physical coordinate measurement machine and even more, because, for example, internal and hidden geometries can also be measured quickly and non-destructively.

Nominal/Actual Comparison

With VGSTUDIO MAX, you can compare your scanned cast part with its respective CAD data set: For fast detection and evaluation of shrinkage behavior and warpage, of missing or not poured areas of the casting, of sink marks and cold flow issues at castings, or upcoming wear and tear in molds. Color-coded comparisons provide easy-to-understand visual information of deviations. Manual, automated, or rule-based annotations provide local point- or area-based information, for example, to locate the three largest deviating areas or a specific number of predefined points.

Wall Thickness Analysis

Different wall thicknesses and especially large jumps in wall thickness have a major impact on the flow and solidification behavior of the melt in the mold cavity as well as on the shrinkage behavior including the induced, often unfavorable stresses, the amount, position, and shape of the porosities, and thus on the overall mechanical and physical properties of the casting. With VGSTUDIO MAX, you can determine the actual wall thicknesses in the casting and thus get an insight into the potential problem areas, e.g., material buildup. You can automatically measure the wall thicknesses or wall distances for almost parallel surfaces as well as for curved or branched surfaces.

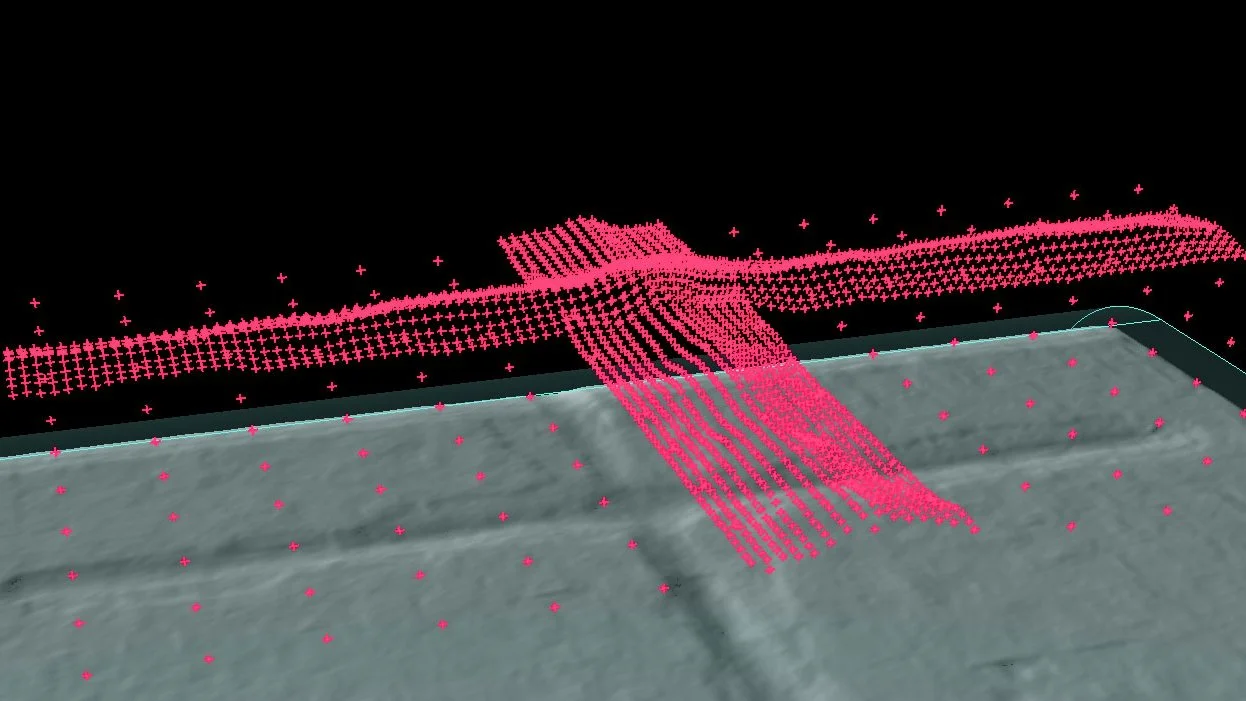

Mold Cavity Correction

The casting mold is often the cause behind geometric deviations of the cast component. With VGSTUDIO MAX, you can correct your casting tools in a seamless digital workflow with a lower number of iterations. Use scans of your sample part to precisely calculate any necessary changes to the mold. Export information on the newly calculated surfaces quickly and easily as a CAD object—and thus create an optimal part/mold fit in just a few steps.

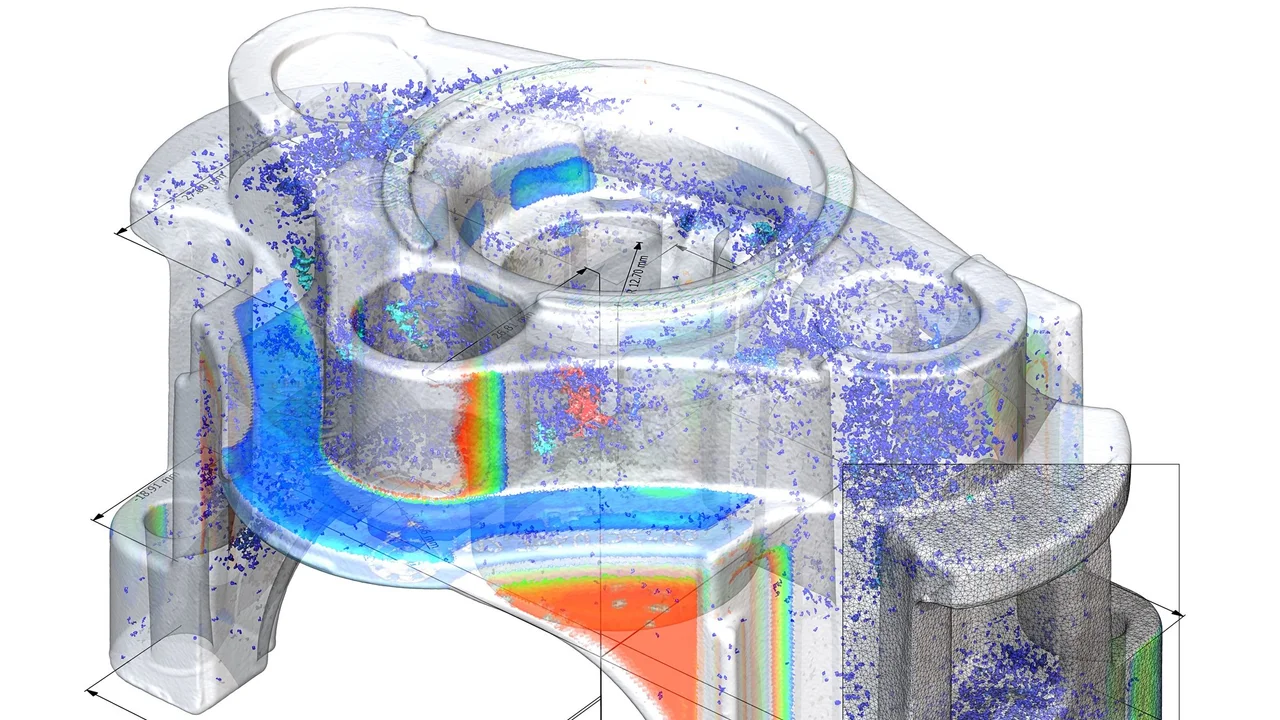

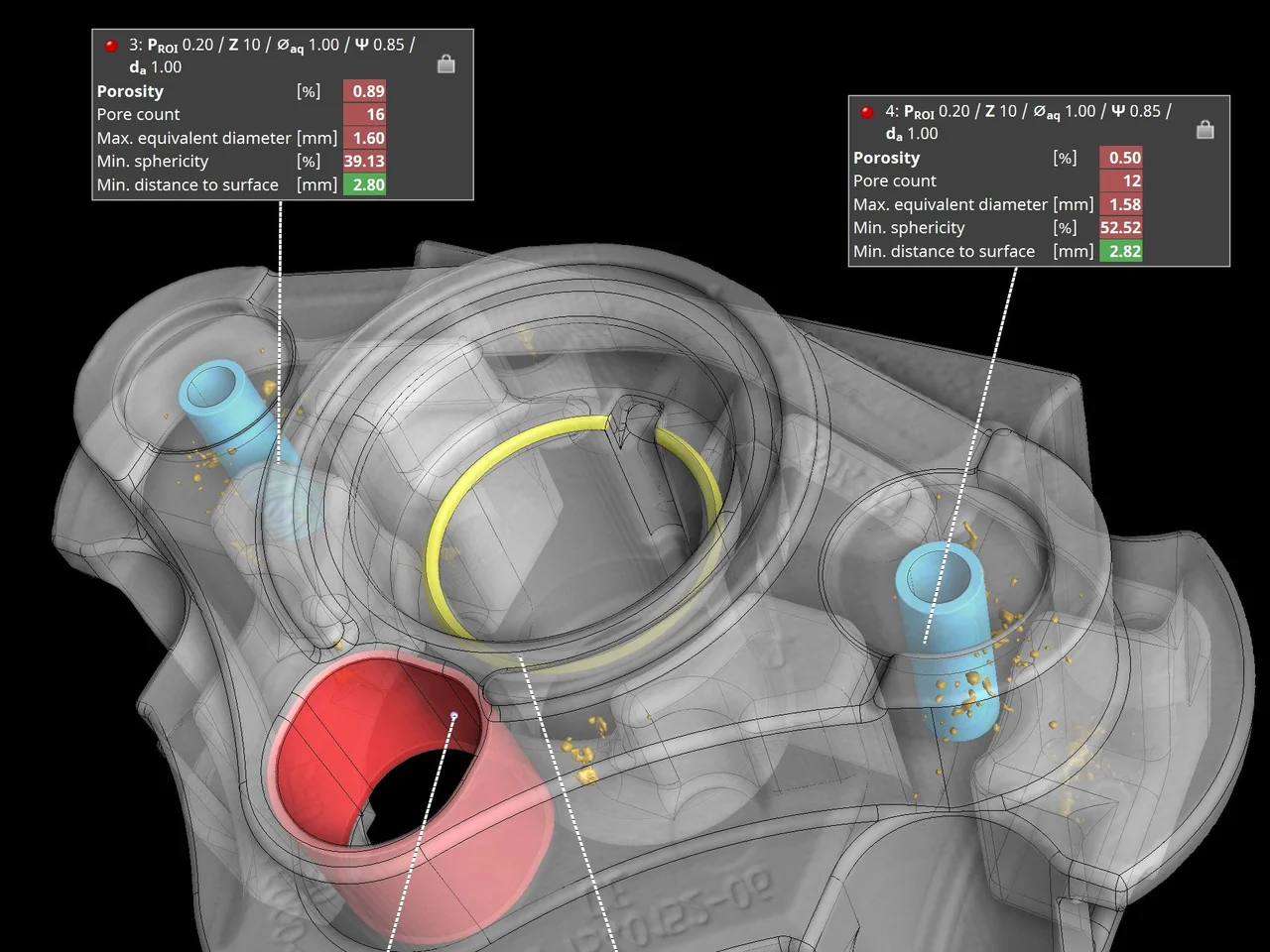

3D Porosity and Inclusion Analysis

Casting comes with challenges like voids, porosity, and cracks in the final product. With VGSTUDIO MAX, you can reliably detect discontinuities in castings, such as pores and cracks, even in lower-quality data, and determine their sizes and shapes. You can also calculate the defect size relative to the local wall thickness. Filtering the results by properties, such as sphericity, compactness, or distance to surface, allows you to distinguish between different mechanisms of porosity formation, such as air entrapments, gas porosities, and shrinkage cavities. Tolerancing criteria can also be adapted to different regions of the component.

P 201, P 202, and P 203 Analyses

In the automotive industry, special rules for porosity detection apply. VGSTUDIO MAX supports three of the most important guidelines for porosity analysis in order to make evaluations for cast parts easily understandable and reproducible: BDG Reference Sheet P 201, P 202, and P 203.

VDG Specification P 201 (VW 50097) and BDG Reference Sheet P 202 (VW 50093) provide a digital, fully nondestructive take on the classic micrograph analysis, which was achieved by sawing open the component. The BDG Reference Sheet P 203 not only extends VDG P 201 and BDG P 202 to 3D but also puts an additional focus on the specific assessment of functionally relevant part areas by using freeform regions.

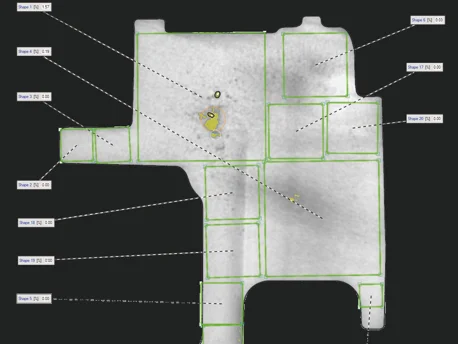

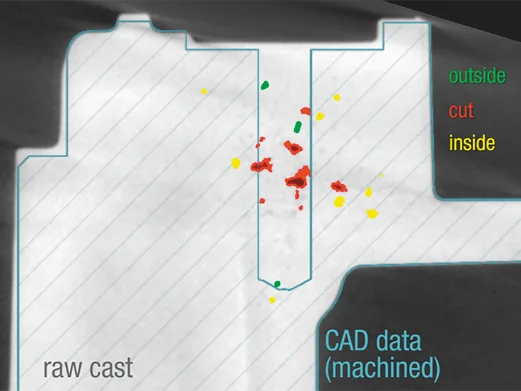

Virtual Machining

Porosities in the wrong places can have serious consequences for the further machining of a casting. That’s why VGSTUDIO MAX shows you if and how porosities like gas pores, air entrapments, or shrinkage cavities would be cut during machining—before actually machining the part (CAD file of the part required)

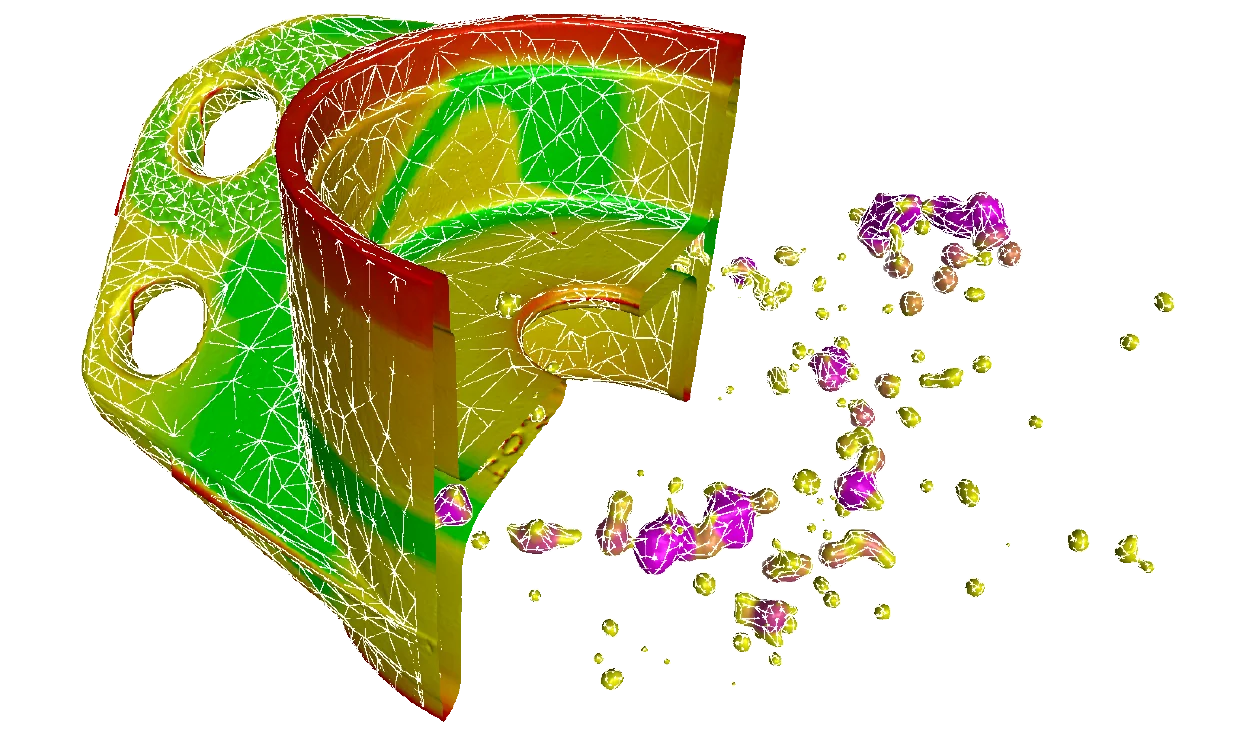

Effect of Defect Simulation

Geometrical flaws and porosity can affect the mechanical strength of a cast part. VGSTUDIO MAX allows you to apply loads and constraints to the CT-scanned model and to simulate and visualize stress concentrations caused by geometrical flaws and porosities—without volume meshing, without prior simulation experience, and without leaving the familiar software environment of VGSTUDIO MAX.

FEA (Finite Element Analysis) or FAT (Fatigue Simulations) reveal aspects of a casting that are not visible in a static analysis of its properties and imperfections. For simulation in third-party software, you can use VGSTUDIO MAX to quickly create high-quality tetrahedral volume meshes that take into account and represent the actual geometries and internal discontinuities of the casting.

A loss of geometrical information is avoided by the omission of an interposed surface meshing, which at the same time saves a lot of time. Each cell of the generated volume mesh can be loaded with simulation-relevant information, such as data from a porosity analysis.

Automated Inspection in Production

It is becoming increasingly important for parts to be not only inspected comprehensively but also directly where they are produced. With VGinLINE, you can semi- or fully automate the quality control process of cast parts (including the automatic recognition of tool cavity markers). It can cover the entire process from reconstruction of the CT data to inspection, reporting, and manual review.

Connection to Auxiliary Systems

Not only can the quality control process of cast parts be semi- or fully automated. It can also be connected to auxiliary systems like statistics, ERP, or MES software via standard file formats. To centrally store CT results in quality management or statistical process control software, you can export certain analysis results using the widely used Q-DAS data exchange format.

Book Free Workshop Now

Join us in room Krakau (NCC East, level 2) for a free 60-minute workshop at EUROGUSS 2022. Under the title "How does the caster perform non-destructive 3D CT porosity analysis with VGSTUDIO MAX?" our casting expert Andreas Harborth will explain and demonstrate the analysis of castings and give you an overview of the application potential of VGSTUDIO MAX in light metal foundry. You can choose from three sessions: Wednesday, 2:30 pm, Thursday, 2:30 pm, and Friday, 1:00 pm. Use the form below to register: